Fusion will be closed on ANZAC Day Thursday (25/4) + Friday (26/4). Our normal hours will resume on Monday (29/4).

A carbon absorption degassing chamber is a device which removes contaminants and dissolved gases from high purity water. This was the first degassing chamber designed and commissioned by Fusion; making it an exciting and challenging project requiring close communication with the client, to build the best polyethylene (PE) solution.

Degassing towers are completely mechanical, and require no chemical treatment, and as such they are good for the environment.

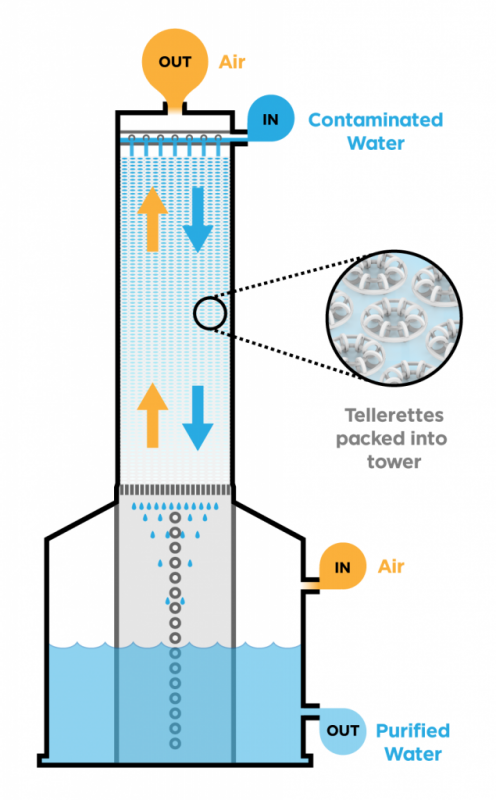

The cross-section diagram (shown) details the process performed by a degassing chamber:

This project was our first requiring Registered Professional Engineer of Queensland (RPEQ) Certification. Fusion engaged an RPEQ Engineer to work alongside our in-house Mechanical Engineer to help develop the most suitable solution.

The customer requested a 20 year design life; which we were able to provide. Price and delivery constraints also needed to be factored into the design.

The aim: to fabricate a tower out of high density polyethylene (PE) which would enable the client to remove carbon from the water. This water would already pass through a reverse osmosis (RO) process and, after removing the carbon, enable it to be used in the processing of nitrates.

Generally, carbon absorption degassing chambers are built with stainless steel or fibreglass. However, PE offers a more cost-effective solution while having the additional advantage of being resistant to corrosion.

The design of the chamber consists of two main components: a 13kl tank and a four metre high tower containing tellerettes. Inside the tank is a perforated internal structure to support the tower above. The tank also incorporates three low pressure relief valves manufactured from PVC. These were necessary to act as a fail-safe device in the event of tower blockages and are unique in design; further requiring RPEQ certification.

Cost effective: PE is cheaper than steel.

Corrosion resistant: reduced maintenance costs, greater longevity.

Lighter in weight: easier to transport and install.

Unique low pressure release valves: reduce possible downtime along with maintenance costs. The reduced maintenance costs offers a quicker return on investment for our client.

Our engineering and fabrication team enjoyed the challenge this project provided. Working with an RPEQ engineer was a first for Fusion; the team certainly learned and benefited from the experience. The Fusion Brisbane staff enjoyed working closely with the client on such a exciting and challenging project.