Materials and Easier Transport

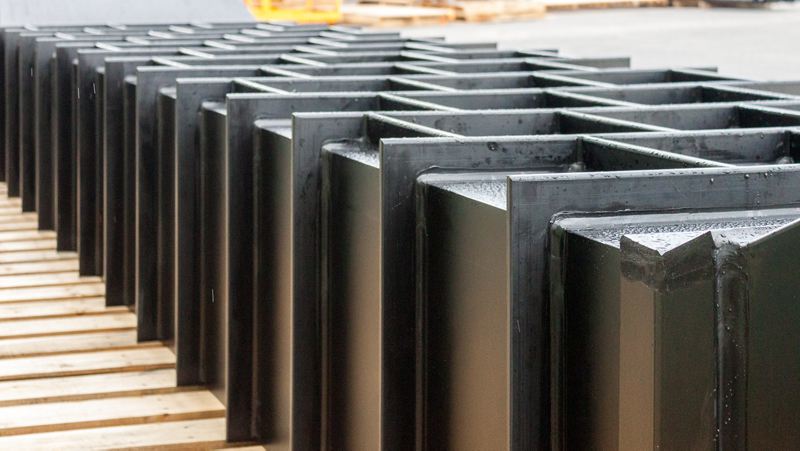

Typically culverts are made from pre-cast concrete or steel. When a plastic culvert is required, polyethylene (PE) is often the plastic of choice for its great weathering and corrosion resistance, light weight and flexibility. The final culvert design measured 5m long with a 1m x 0.5m HDPE rectangular section. The lightness of HDPE allows for this culvert to be easily lifted with a crane or forklift, making transport and installation relatively simple.

One Point Of Communication For the Entire Project

We were initially contacted by our client to quote for the supply of Polyethylene PN10 pipe & fittings, however, after discussions and an explanation of our fabrication capabilities, the quote expanded to include the fabrication of a culvert. Being able to communicate with one company for both the culvert fabrication and supply, was a major contributing factor for the client awarding to project to Fusion.

The client only needed to communicate with one company for the entire supply and fabrication of their design; making it much easier to coordinate deadlines, get status updates, eliminate part/materials shipping between 3rd parties and collaborate with Fusion’s engineers, fabricators, installers and technical sales team.