The $300M Mundaring Water Treatment Plant (WTP) is a critical asset in the long term supply of safe and high quality water to Western Australia’s Goldfields & agricultural regions. Fusion worked with Acciona JV and the Water Corporation to design, fabricate and install various key water processing components in the WTP.

Built nearly 120 years ago, the Mundaring Weir supplies water to WA’s Goldfields and Agricultural Region, serving more than 100,000 people from Mundaring to Kalgoorlie. To cater for increasing water demand, meet the needs of future residential and industrial growth, and maintain current Australian drinking water guidelines (as well as overcome a decline in water qualities including colour, odour and taste) the Mundaring Weir Water Supply Improvement Project (MWWSIP) was developed to construct a number of new assets and carry out asset upgrades.

The Mundaring WTP is a key component of the MWWSIP. It has a current capacity to supply 165,000 cubic metres per day of drinking water, with an ultimate capacity to supply 240,000 cubic metres per day. The WTP uses dissolved air flotation filtration (DAFF) and biological activated carbon (BAC) to remove suspended solids and organic compounds from water.

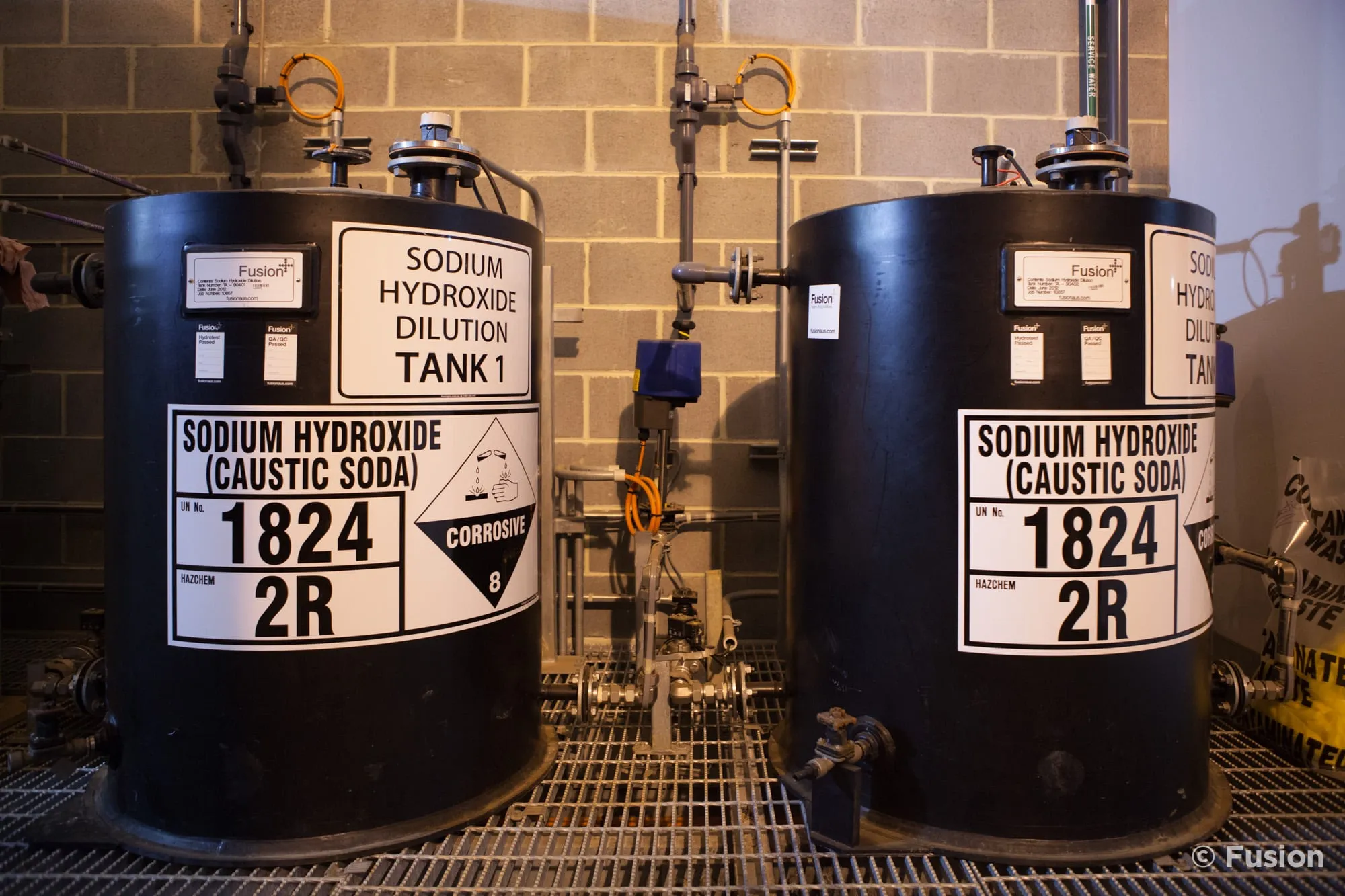

Fusion designed, fabricated, supplied and installed a range of key components in the water treatment process including:

The project required plant components with a long design life to ensure minimal down-time and reduced need for replacement. Fusion’s engineering team designed and installed components to meet the particular requirements of the Mundaring WTP, maximising design life and providing a long-term and safe solution for the facility, including PE storage tanks with a 25 year design life, specific to the chemicals being stored at the WTP.

Fusion’s long history in designing and fabricating chemical dosing panels has allowed us to develop (and continually improve) the design to ensure maximum safety for the plant operators.