How do many industries safely store and transport a wide range of chemicals and liquids? One answer lies in the use of plastic-fabricated tanks. These versatile tanks offer numerous benefits, such as durability, low maintenance, and chemical resistance, making them ideal for various applications.

In this article, we will delve into the world of chemical storage tanks, exploring the advantages, materials, and customisation options available, as well as their various applications in industries such as chemical storage and wastewater treatment. By the end, you will have a more thorough understanding of plastic fabricated tanks and their advantages.

Plastic-fabricated chemical storage tanks offer exceptional durability and minimal maintenance, making them suitable for various industrial applications.

Customisable capacity, size, fittings and accessories provide reliable storage solutions while meeting industry standards.

Chemical compatibility guides help identify the appropriate material for their chemical storage applications.

Plastic tanks are renowned for their exceptional durability, thanks to their construction from robust and durable materials, such as:

These materials are commended for their toughness and ability to resist chemicals. They each possess unique characteristics, such as temperature tolerance or UV resistance, enabling the selection of the most suitable plastic for a specific application.

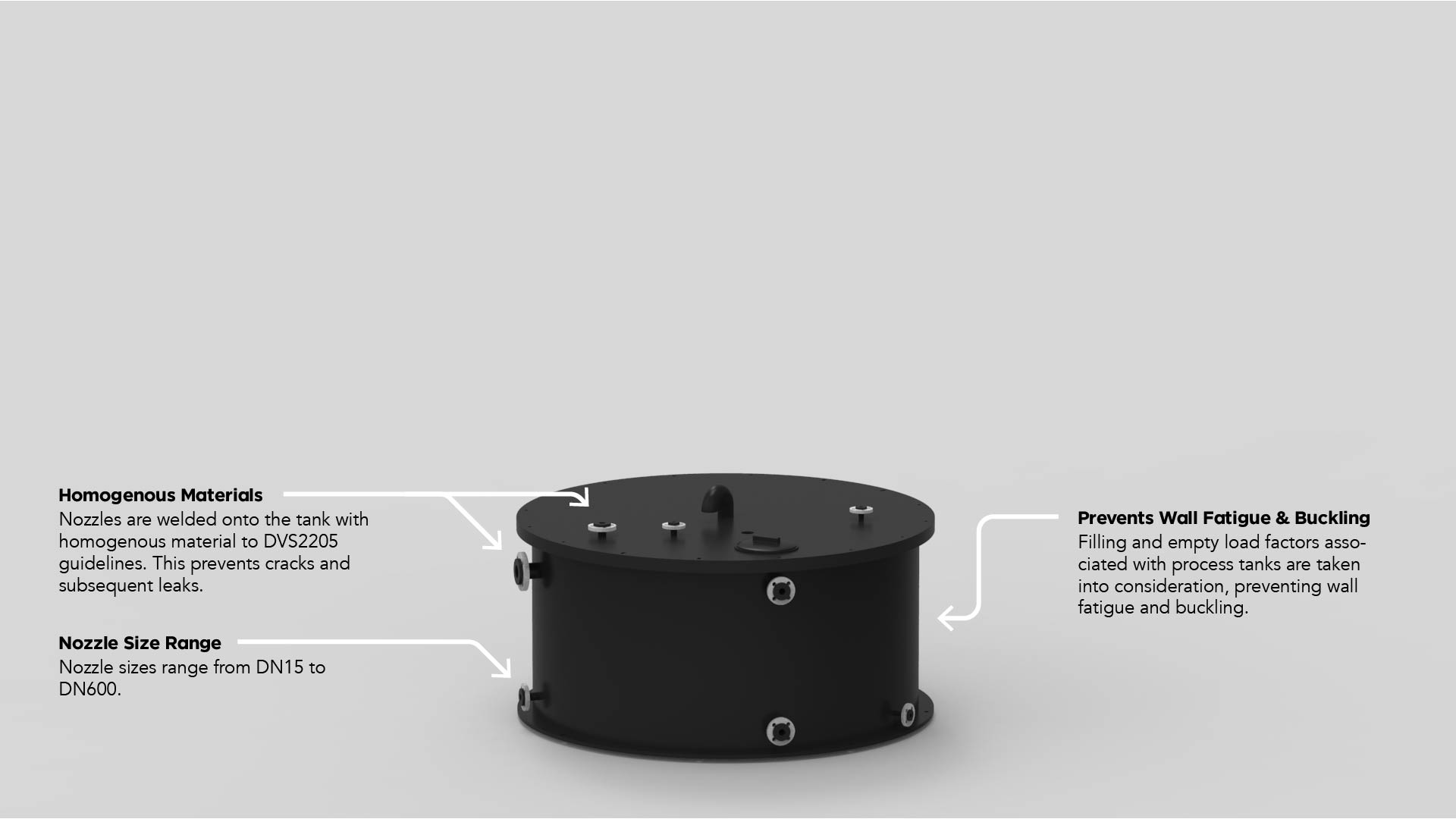

Another advantage of plastic-fabricated chemical storage tanks lies in their minimal maintenance needs. The materials used in their construction, such as high-density polyethylene and polypropylene, contribute to their strength and chemical resistance. Fittings installed on fabricated tanks can be selected from the same material as the tank walls, ensuring material homogeneity throughout the entire system and reducing the chance of cracks at joints between the tank and inlets/outlets.

A significant advantage of fabricated chemical storage tanks is their customisability. They're not made using molds, allowing for numerous design customisations in shape, size, and optional extras, such as rated lifting lugs.

Dual-wall chemical tanks can also be designed with an inner wall material selected for its durability against contact with the stored chemical and an outer wall material chosen for its ability to withstand the chemical tank's environmental conditions, such as high temperatures and UV exposure. The gap between the two walls can serve as a bunding area or be filled with optional insulation for added strength and thermal insulation.

Plastic tanks offer a lightweight alternative to metal tanks, while the addition of rated lifted lugs makes installation significantly easier. This is a significant advantage in scenarios where quick installation is required or where access to the installation site is limited. The reduced weight of plastic tanks also means less strain on supporting structures and foundations, potentially saving on infrastructure costs. Additionally, the inclusion of rated lifting lugs in the design facilitates easier installation and provides a secure and safe method for tank transportation. This can be particularly beneficial in industries where tanks need to be regularly moved or transported between different locations.

As a result of these benefits, fabricated tanks can be manufactured with a design life of up to 25 years.

Polypropylene (PP) and high-density polyethylene (HDPE) are the most popular choices for industrial tank construction.

HDPE offers excellent abrasion and corrosion resistance, making it an ideal choice for industrial chemical storage tanks. HDPE provides:

Environmental stress cracking resistance

PP offers excellent impact, chemical, and abrasion resistance with an operating temperature of up to 90˚c. Standard PP doesn't offer UV resistance; however, its higher operating temperature makes it more suitable than PE in some applications.

These qualities make HDPE and PP ideal for safely storing various substances. Fusion has manufactured chemical storage tanks from sheet HDPE up to 40mm and PP in similar thicknesses. When selecting a thickness, variables such as seismic forces and wind loads are taken into consideration.

The size and capacity of plastic fabricated tanks are adaptable to specific applications, with a maximum height of 10 meters, factoring in specific gravities. Round tanks, in accordance with DVS 2205, should have a diameter not exceeding 4 meters and a height not exceeding 6 meters, ensuring a suitable range of chemical storage capacities.

Compared to rotomolded plastic tanks, plastic-fabricated tanks present distinct advantages. Rotomolded plastic is created using rotational molding, which involves heating and rotating plastic powder in a mould to form various plastic products.

While the heating and moulding process of rotomolded tanks allows the plastic to coat the mould, it can result in varying wall thickness, potentially leading to weaker areas on the tank. In contrast, fabricated chemical storage tanks from Fusion are constructed from plastic sheets that undergo butt welding and extrusion welding. These sheets have a consistent thickness and are available in various sizes to cater to specific chemical storage needs.

Rotomolded tanks are created using specific moulds, which inherently limits their size and shape to the dimensions and configurations of the available moulds. This means that the customisation of these tanks is restricted, offering less flexibility for unique or specific applications. On the other hand, plastic-fabricated chemical storage tanks do not face such limitations. These tanks are custom-made from plastic sheets, allowing for a wide range of sizes and shapes to be achieved. This bespoke approach ensures that fabricated tanks can be precisely tailored to suit specific applications, offering a significant advantage over their rotomolded counterparts.

Rotomolded tanks are typically constructed from low-density polyethylene (LDPE), a type of plastic known for its flexibility and toughness. However, the LDPE walls are often paired with HDPE fittings. The differing material densities and expansion/contraction rates can create stresses at joins, which can cause cracks and leaks. On the other hand, plastic fabricated tanks have the advantage of being crafted from a wider range of materials, including high-density polyethylene (HDPE) and polypropylene (PP). The fittings used on fabricated chemical tanks are generally made from the same material as the tank walls, ensuring consistency in the tank's construction and significantly reducing the likelihood of cracks at joins.

In conclusion, while rotomolded tanks have their place in the market due to their cost-effectiveness and suitability for water storage, when it comes to industrial storage, fabricated tanks generally outperform them and lead to significant cost savings in the long run. Fabricated tanks offer a longer lifespan and require minimal to no maintenance, provided they are used for their intended application. This makes them a more advantageous choice for complex industrial applications requiring robust, durable, and highly customisable storage solutions.

The latest Australian Standard for the storage and handling of corrosive substances identifies that "rotationally moulded polyethylene tanks larger than 5m³ can have a service life of only 5 to 7 years and should be inspected frequently." (AS3780-2023 The Storage and Handling of Corrosive Substances, Section 6.7.3 Tank Design and Construction (subsection d)).

The provided thermoplastic tank, fabricated from sheet, can achieve a design life of up to 25 years when operated according to its manufactured specifications. This is far longer than the standard allows for rotationally moulded tanks.

Thermoplastic tanks are not mandated to be inspected within the standard. However, Fusion strongly recommends inspections for Fusion-fabricated tanks to ensure the safety of people and the environment. These inspections will likely require less frequency than those for rotationally moulded tanks.

Lastly, the standard states rotationally moulded tank inspections "shall include evidence of cracking, leakage and connections and for tanks becoming out-of-round due to load cycling and/or temperature variations" (AS 3780-2023 The Storage and Handling of Corrosive Substances, Section 6.7.3 Tank Design and Construction (subsection d)). Fusion plastic fabricated chemical storage tanks are far less susceptible to these issues as homogenous materials are used throughout.

Plastic fabricated industrial tanks are widely utilised across various industries, including:

These tanks are employed in diverse applications and play a crucial role in different processes. Plastic fabricated industrial tanks' remarkable durability and corrosion resistance account for their widespread use across these industries. Their lightweight and easy installation make them suitable for industrial wastewater and process water management, while their cost-effectiveness and customisation options allow them to be tailored to suit specific requirements.

Plastic fabricated industrial tanks, with their chemical resistance and durability, offer immense benefits for chemical storage solutions. Some advantages of plastic fabricated chemical storage tanks depend on the chosen material; these can include:

Given their durability and low maintenance attributes, industrial chemical storage tanks made from plastic materials are ideal for managing wastewater and process water. Polyethylene and polypropylene are the main materials used in water treatment tanks, with external steel frames providing support if necessary. Using plastic tanks in wastewater treatment plants offers several advantages, including their ability to withstand harsh chemicals and resist corrosion, ensuring a long service life.

A primary advantage of plastic-fabricated tanks is their flexibility in customisation to meet specific needs. Customisation options include capacity, size, fittings, and accessories. These tailored solutions allow for precise specifications and ensure that the tanks are suitable for various applications, from chemical storage to wastewater treatment.

For example, single- and double-wall tanks offer different capacity and size options to suit specific needs. Additionally, fittings and accessories such as valves, pumps, level indicators, and other components can be customised to enhance the functionality and performance of the tanks. This level of customisation ensures that plastic fabricated tanks can be adapted to a wide range of industrial applications, providing reliable and efficient storage and transport solutions.

The design of plastic fabricated chemical tanks can be varied in terms of capacities and sizes to fulfil specific requirements. Common capacity options include:

When choosing a plastic fabricated chemical tank, it is important to consider the specific capacity and size requirements of the application. Fusion can assist with determining the right size and material for the tank to ensure safe storage and transportation of chemicals, water, or other liquids, while also accommodating space constraints and environmental considerations.

To boost the functionality and performance of Fusion plastic fabricated tanks, fittings and accessories can be tailored to specific needs. These options include:

By selecting the appropriate fittings and accessories, Fusion ensures that its plastic chemical tanks are well-suited for specific applications such as chemical storage, water treatment, or other industrial processes. For instance, a chemical storage facility may need specialised fittings to safely transport hazardous chemicals, while a wastewater treatment plant may require specific pumps and level controls to manage the treatment process efficiently.

Customising fittings and accessories allows plastic fabricated tanks to be tailored to meet the unique needs of each application, providing a reliable and efficient storage solution.

The production of plastic fabricated tanks incorporates sheet fabrication techniques and rigorous quality control measures, ensuring adherence to industry standards. These tanks are generally manufactured from sheet polypropylene or high-density polyethylene, with various methods being employed in the production process, such as:

Quality control plays a vital role in the manufacturing process, safeguarding the safety and durability of the end product. For example, Fusion Plastics is a renowned Australian plastic fabricated tank manufacturer and is certified to ISO 9001, the international standard for quality management. This level of quality assurance ensures that plastic fabricated tanks are reliable and long-lasting, making them a popular choice across various industries.

In the production process of plastic fabricated tanks, quality control and compliance play a pivotal role in ensuring safety and durability. By adhering to strict quality control measures and industry compliance standards, Fusion can ensure that Fusion plastic fabricated tanks are reliable and safe for their intended applications. This level of quality assurance gives customers confidence in the performance and longevity of their plastic fabricated tanks, making them a popular choice for many industries. Fusion chemical storage tanks are manufactured according to DVS 2205 standards and undergo quality inspections and hydro testing as standard to ensure leak-free, strong and long-lasting chemical storage.

The appropriate plastic fabricated tank is selected based on chemical compatibility and environmental considerations. The relationship between the plastic tank and its contents is crucial when storing chemicals. The type of chemical, its concentration in solution, and the storage temperature all play a role in determining the suitable type of plastic for containment. Consulting a chemical compatibility expert is essential when selecting a storage tank to ensure secure storage of chemicals.

Environmental considerations, such as temperature and UV exposure, should also be taken into account when selecting a plastic fabricated tank. Temperature can influence the strength and longevity of the tank, as well as the chemical resistance of the material. UV exposure can cause the plastic to degrade over time, potentially leading to cracks and leaks.

By considering these factors, companies can select the most appropriate plastic fabricated tank for their specific application, ensuring a reliable and efficient storage solution.

Fusion can provide assistance when choosing the most suitable plastic for specific applications. Contact us today with your specific application.

A chemical compatibility guide aids in identifying the suitable material for a particular chemical storage application. This crucial resource assists in selecting the most suitable material for a given chemical storage tank application, ensuring that the tank can safely store and transport the intended substances.

Chemical compatibility guides can be found online; however, some may offer slightly differing results and should be used as a guide only. An excellent resource for researching compatibilities is Simchem by Simona (requires free registration to use). By consulting these resources, companies can ensure that their plastic fabricated tanks are suited for their specific applications and operations, whether it be chemical storage, water treatment, or any other industrial process.

Important environmental factors like temperature and UV exposure should be taken into consideration while choosing a plastic fabricated tank. Temperature can affect the strength and longevity of plastic fabricated tanks, in addition to the chemical resistance of the material. For example, a tank storing chemical in a hot environment may require a different material than one storing chemical in a cooler environment.

Case studies exemplify the successful integration of plastic fabricated tanks across various industries, such as chemical storage facilities and wastewater treatment plants. These real-world examples demonstrate the versatility and effectiveness of plastic fabricated tanks and their ability to provide reliable and efficient storage solutions across a range of applications. You can find a variety of Fusion's case studies online, and a large collection of Fusion's previous work can also be seen on our Flickr page.

Fusion chemical storage tanks have proven to be a valuable asset in numerous industries, from chemical storage facilities to wastewater treatment plants.

Plastic fabricated tanks offer numerous benefits, such as durability, low maintenance, and chemical resistance, making them ideal for various industries and applications. By understanding the advantages, materials, and customisation options available, as well as considering factors such as chemical compatibility and environmental considerations, companies can select the appropriate plastic fabricated tank for their specific needs. With successful implementations across various industries, including chemical storage facilities and wastewater treatment plants, plastic chemical storage tanks have proven to be a valuable and reliable storage solution for countless applications.

Fusion can provide assistance when choosing the most suitable plastic and create designs for specific applications. Contact us today with your specific application.

All materials have their issues; steel can corrode and is heavy, and plastic can melt and degrade; however, many of these issues result from either cost-cutting measures or incorrect choice of material for the chosen application. Fusion does not manufacture plastic water tanks, particularly for domestic applications, as custom-fabricated tanks are too cost-prohibitive for these applications. Generally, plastic water tanks for residential water storage are made from LDPE, are thin-walled and made using a roto moulding manufacturing process to keep costs down. As a result of the thin wall and material, these tanks can be prone to photo-oxidation, which weakens them and reduces their longevity. Signs of photo-oxidation include discolouration, cracking, chalking, sheen loss, brittleness, and even catastrophic failure. Fusion tanks are manufactured to suit specific applications using thick plastic sheets and DVS standards. If continued usage is within the intended application, we offer a design life of up to 25 years.

The short answer is yes. They're lightweight and can provide long term water storage with food-grade safe, BPA-free polyethylene plastic so they're safe for storing drinking water.

Polypropylene and high-density polyethylene are the primary materials used for plastic fabricated tanks. More information about these materials is available above within in this article.

Fusion plastic fabricated tanks offer more customisation, higher strength and crack resistance and considerable longevity. They are therefore generally and a better fit for many industrial applications compared to rotomolded plastic tanks.