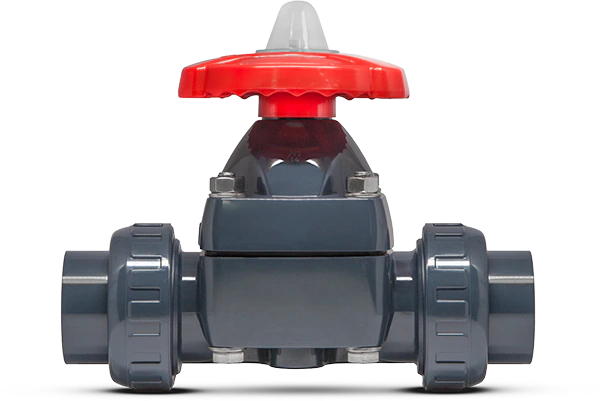

| Sizes | 0.5 – 4inch |

| Bodies | UPVC, CPVC, PP & PVDF |

| Diaphragm | EPDM & 3-Layer EPDM/PVDF/PTFE Nitrile & FKM also available |

| Body Type | True Union (0.5 – 2inch) Flanged (0.5 – 4inch) |

| End Connectors | PVC, CPVC: IPS socket, flanged or threaded PP, PVDF: IPS & metric (DIN) socket, threaded, butt or flanged |

| Bonnet | PVC, PP, PPG and PVDF |

| Operator | Handwheel |

For more information visit the Asahi America website.

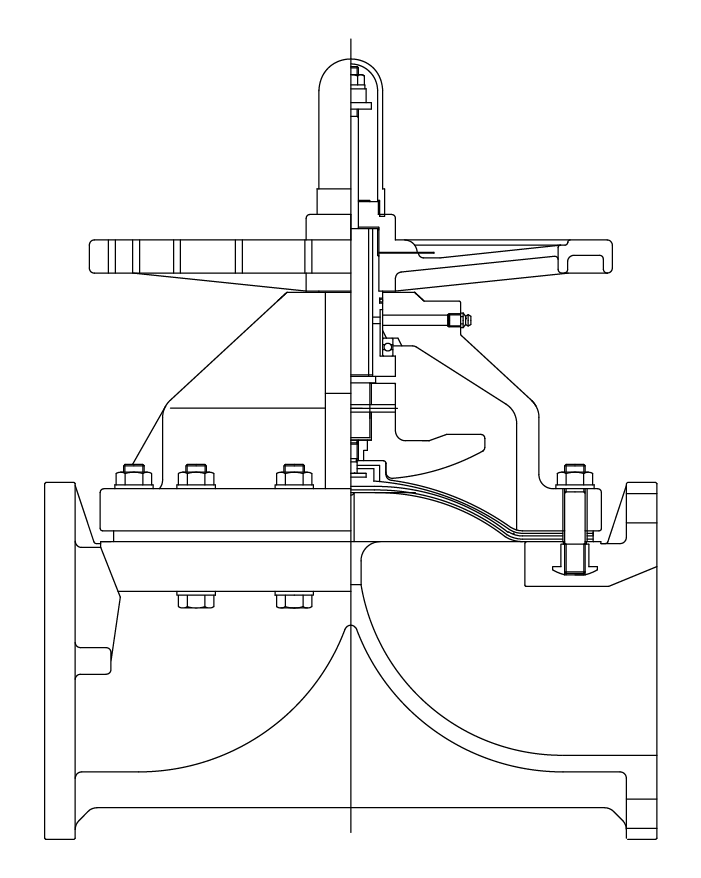

| Sizes | 5 – 6inch |

| Bodies | UPVC, PP & PVDF |

| Diaphragm | EPDM, 3-Layer EPDM/PVDF/PTFE, Nitrile |

| Body Type | Flanged |

| Bonnet | PVC, PP, PPG and PVDF |

For more information visit the Asahi America website.

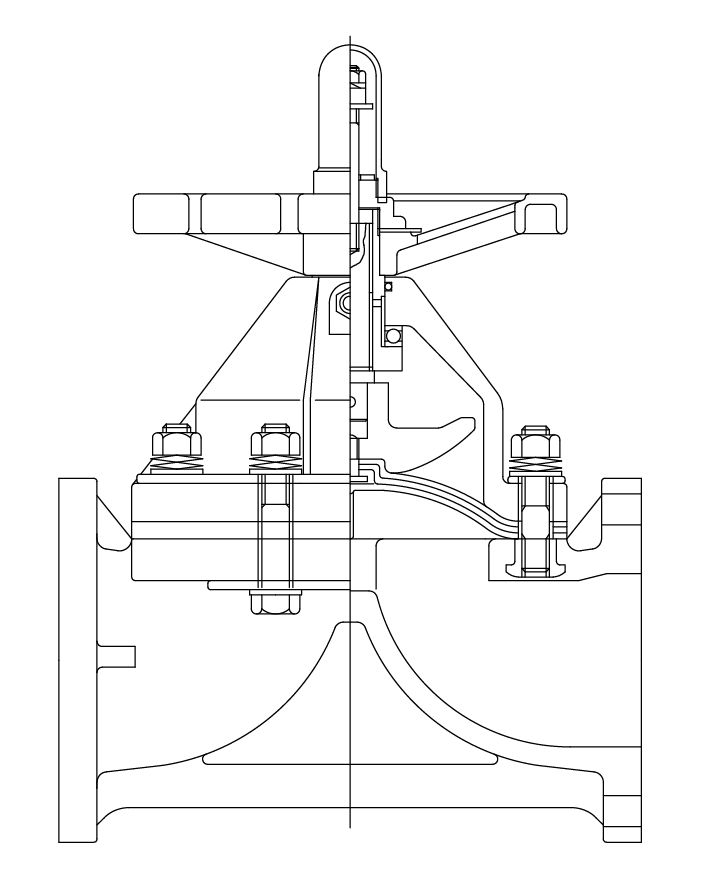

| Sizes | 8 or 10inch |

| Bodies | UPVC, PP & PVDF |

| Diaphragm | EPDM and 3-Layer EPDM/PVDF/PTFE Also available in Nitrile |

| Body Type | Flanged |

| Bonnet | PVC, PP, PPG and PVDF |

For more information visit the Asahi America website.