For the full range available from Fusion download the Fusion Product Guide or Contact us.

Visit The Charlotte Pipe Co Technical Hub for more information about Charlotte's product certifications.

Visit The Charlotte Pipe Co Technical Hub for more information about Charlotte's product certifications.

Download the Sekisui Eslon Schedule 80 catalogue for more information about Sekisui's product certifications.

Download the Sekisui Eslon Schedule 80 catalogue for more information about Sekisui's product certifications.

View more certification information from our supplier, Polypipe Effast

View more certification information from our supplier, Van De Lande

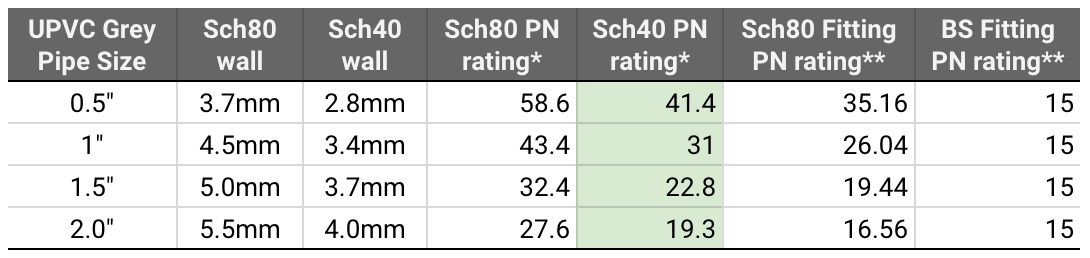

We carry stock of UPVC Schedule 80 pipe and fittings, British standard fittings, solvent cements, primers and accessories to help with installation.