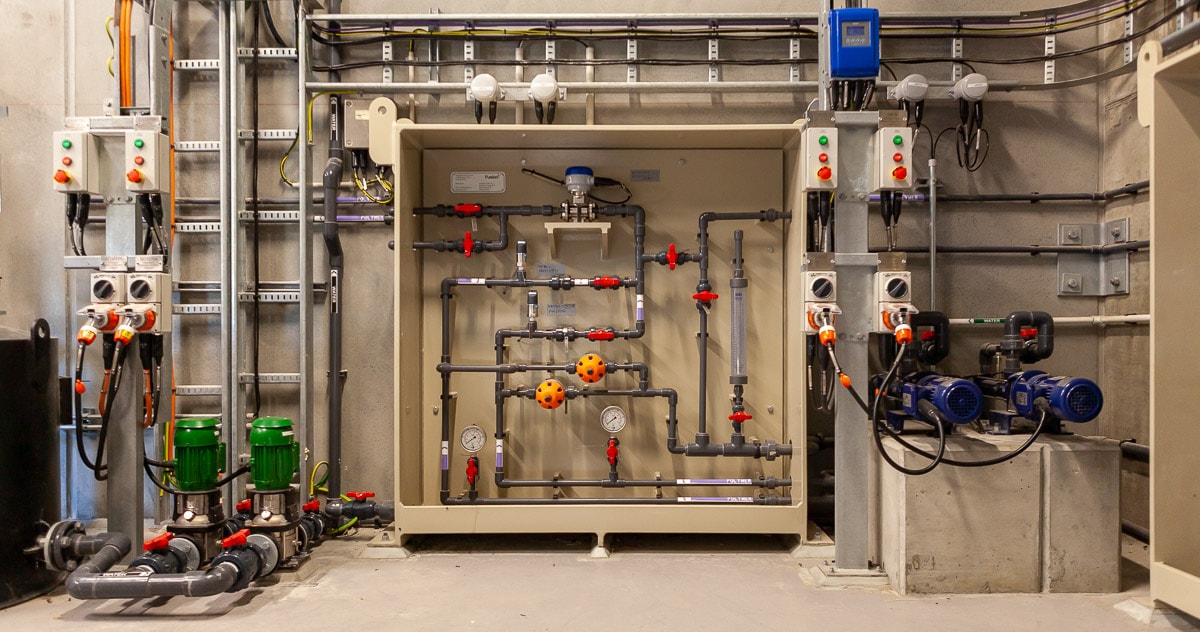

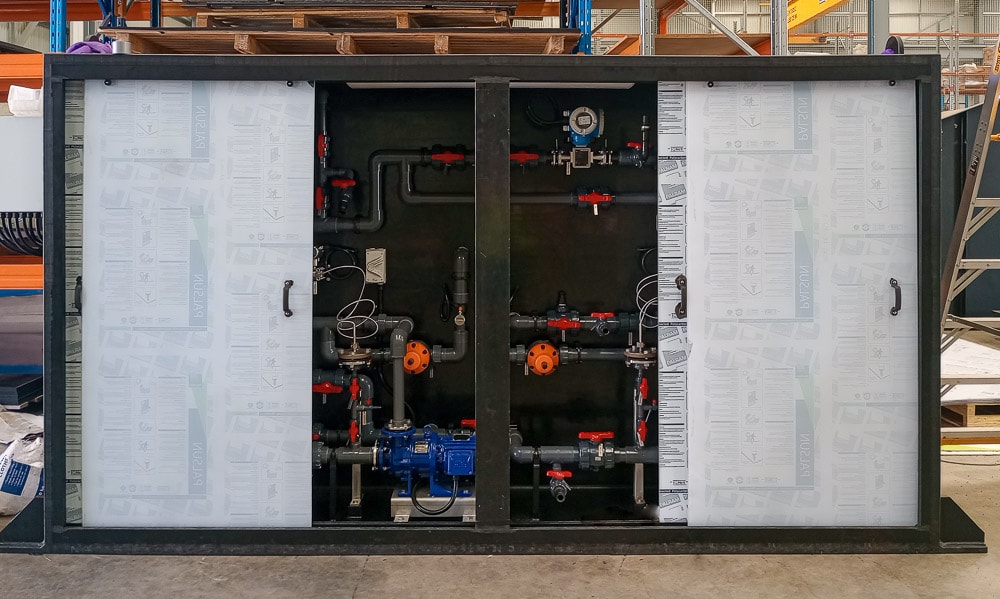

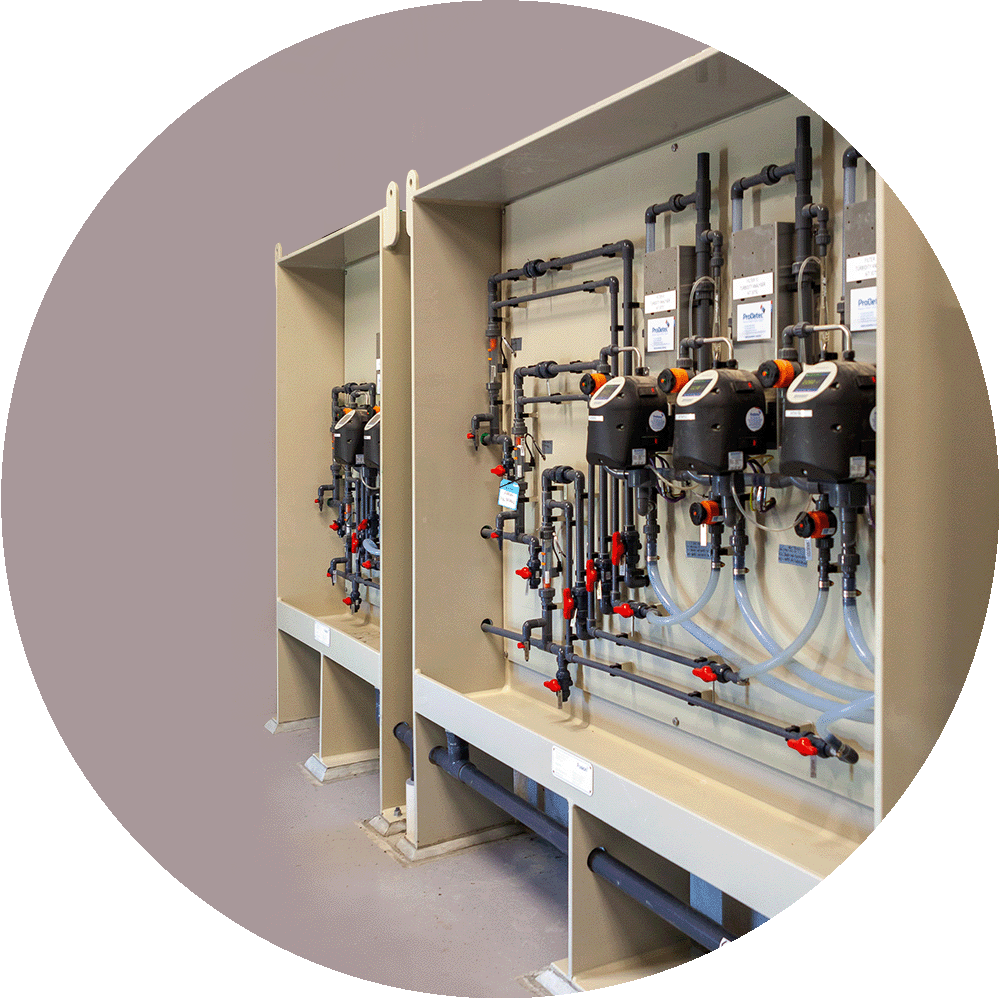

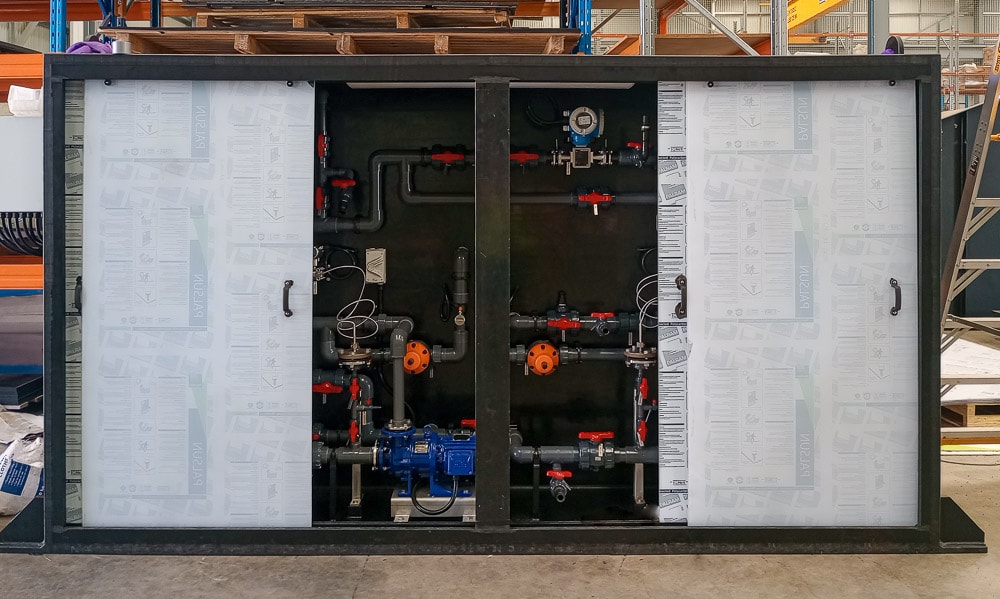

Fusion fabricates chemical dosing panels and cabinets to custom specifications from sheet HDPE or PP, suited to your site and pipework requirements.

Since 1998 we've designed cabinets and panels for use in many processes within Australian industrial plants. These include analyser, injection, pump-in/out, instrumentation, load-in, CIP (Clean in Place) and monitoring panels.

Contact Us Today

Contact Us Today

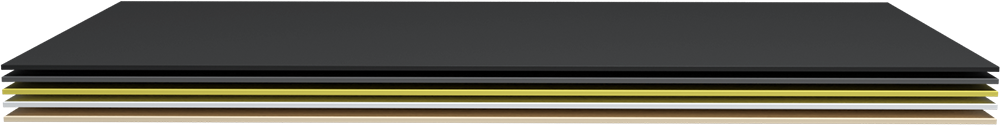

Fusion chemical dosing panels are built from polypropylene (PP) sheet, a thermoplastic with high mechanical strength, great impact, corrosion, chemical and moisture resistance; perfect in applications such as chemical engineering, tank building, ventilation, equipment manufacturing, and laboratory technology and in products such as chemical storage tanks, electroplating barrels, fume cupboards and pipe flanges.

Other plastics such as HDPE (High Density Polyethylene / PE100), PVC, Natural PE and more can be selected depending on factors such as chemical compatibility, UV resistance, and temperature tolerance.

Contact our team to discuss the right plastic for your application.

Since 1998 we've been manufacturing custom industrial plastic chemical dosing panels / cabinets for a range of industries including water treatment, chemical processing, food and beverage, mining, pharmaceuticals and more.

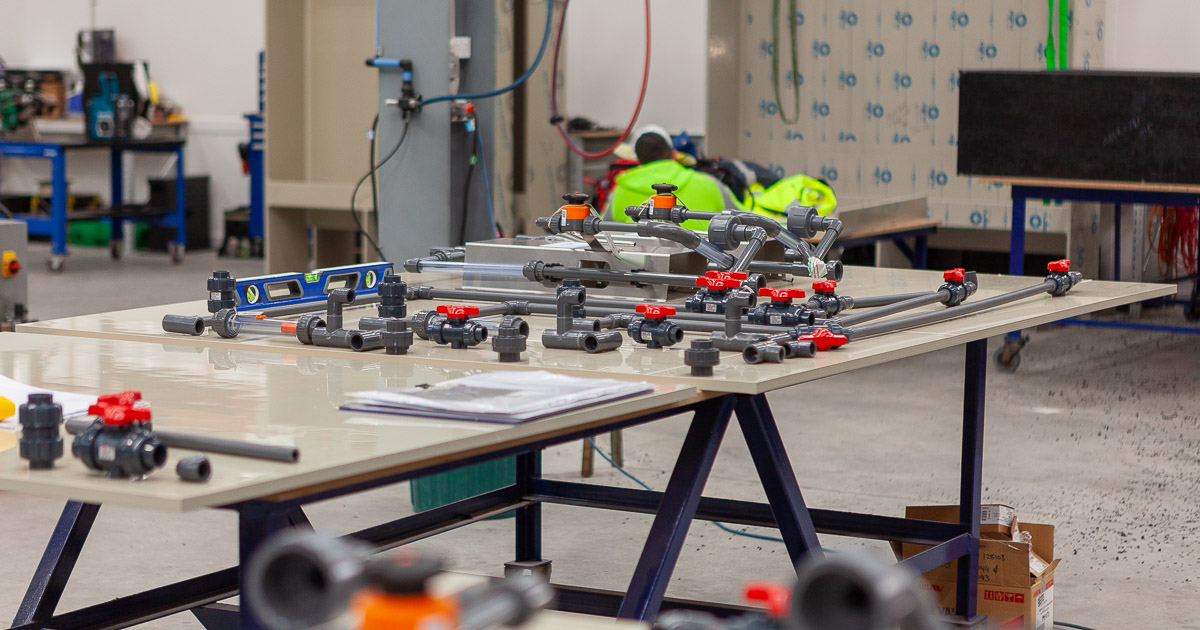

Fusion's site team and plastic fabricators can provide installation and maintenance services that extend beyond dosing panel fabrication. Our teams have expertise in a range of industrial plastic piping systems and are skilled in welding techniques including butt, socket and IR.

Our in-house engineers utilise advanced computer modelling including FEA analysis to design long lasting solutions for clients. Our fabrication facilities use CNC cutting and extrusion welding to build customised, plastic dosing cabinetry designed to suit your site requirements.