Fusion build custom plastic fabricated tanks for clients who require longevity, custom shapes, sizes, nozzle arrangements and hassle free installation and operation for industrial applications primarily in water treatment and chemical processing.

Fusion has chemical storage tank fabrication facilities on the east and west coasts of Australia and utilise large, automatic sheet butt welding machines, CNC cutters, extrusion welding techniques and hydrotesting services to deliver premium chemical tanks for the most demanding environments.

Fusion tanks provide full design flexibility, fully homogeneous materials throughout, full weld identification and traceability (on request). Our tanks are designed to European standards EN12573 and DVS technical codes 2205, are compliant with Australian Standards (including AS3780:2023) and come with a 25 year design life (depending on application).

To create Fusion plastic fabricated tanks, we utilize state-of-the-art sheet CNC butt welding machines for constructing the walls.

For the base and roof, we employ extrusion welding to double-weld to the walls.

These processes achieve consistent wall thickness, ensuring uniform strength across the entire tank, reducing the risk of leaks over time.

All our tanks undergo rigorous inspection and hydro testing to be guaranteed a strong and leak free.

For convenient and secure transport, our tanks can be custom-designed with rated lifting lugs, anchor claws, and vents.

Fusion tanks are designed in accordance with DVS 2205. All extrusion weld sizes and parameters are in accordance with DVS 2205 & DVS 2207-4. All butt welds are in accordance with DVS 220701.

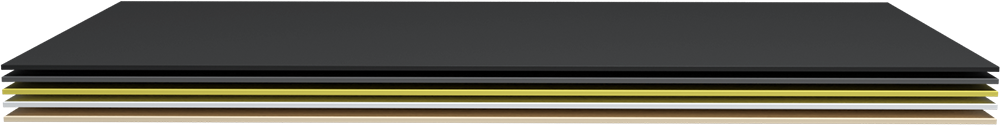

Fusion fabricates custom tanks from plastics such as HDPE sheet (High Density Polyethylene / PE100) or PP sheet (Polypropylene). Polyethylene offers excellent UV and chemical resistance and Polypropylene is selected where higher temperatures are required.

Other plastics such as PVC, Natural PE and more can be selected depending on factors such as chemical compatibility, UV resistance, and temperature tolerance. Contact our team to discuss the right plastic for your application.

Since 1998 we've been manufacturing custom industrial plastic tanks for a range of industries including water treatment, chemical processing, food and beverage, mining, pharmaceuticals and more.

Storing something specific? Our team can specify the best tank material for your application.

Common chemicals our tanks store include:

Fabricated plastic tanks are easy customisable, complex shapes can be manufactured, they can be built to large capacities, they're more durable, easily repairable, offer excellent temperature resistance and can be built to regulatory compliance standards.

We install the highest quality piping system components according to your connectivity requirements.

We've partnered with global manufacturers such as Asahi Valves Co, Charlotte Pipe Co, Effast, Flowline Level Instrumentation & more to provide the best pipe, fittings and devices to suit your next Fusion custom storage tank build.

During our fabrication process we can build and/or install custom bunding to AS3780, lugs, level meters, site glass assemblies and more. Our skilled plastic tank fabrication teams can design and build chemical storage tanks to your specific requirements.

Fusion's site team and plastic fabricators can provide installation and maintenance services that extend beyond tank fabrication. Our teams have expertise in a range of industrial plastic piping systems and are skilled in welding techniques including butt, socket and IR.

Our in-house engineers utilise advanced computer modelling including FEA analysis to design long lasting solutions for clients. Our fabrication facilities use CNC cutting and butt welding, extrusion welding and more to build customised, plastic tanks designed to suit a broad range of liquid and gas storage requirements.

All Fusion polyethylene tanks are designed and manufactured in Australia under strict quality control to client specifications. Plastic tanks can be supplied with a design summary and test certificates for traceability and quality assurance (on request).