Scrubbers are used in a wide variety of industries including:

Scrubbers are traditionally made with stainless steel and fibreglass for their strength, however stainless steel is prone to corrosion and is expensive when used for fabrication. Fibreglass is prone to distortion and cracking due to it’s low impact resistance and not a very cost-effective solution.

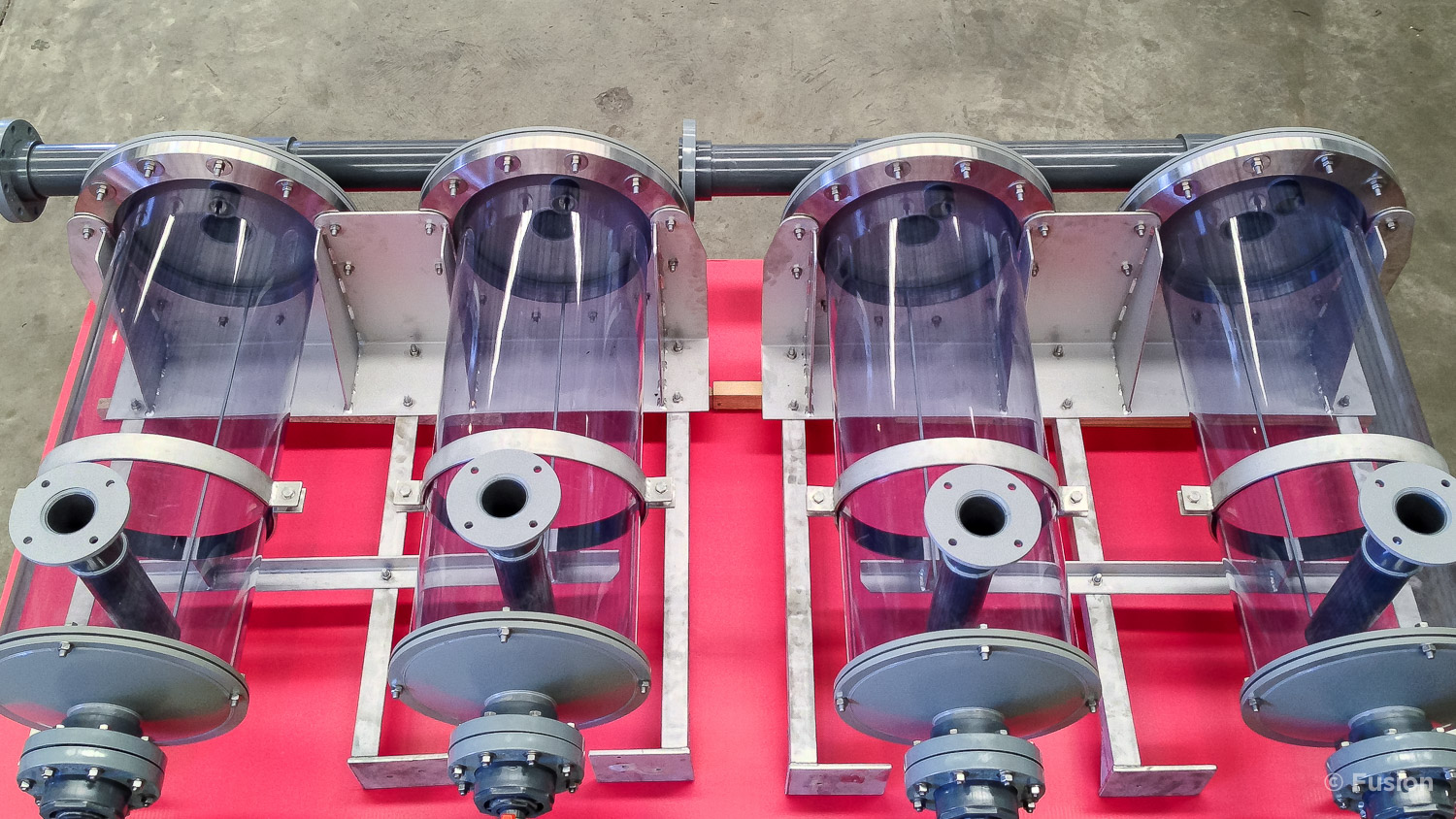

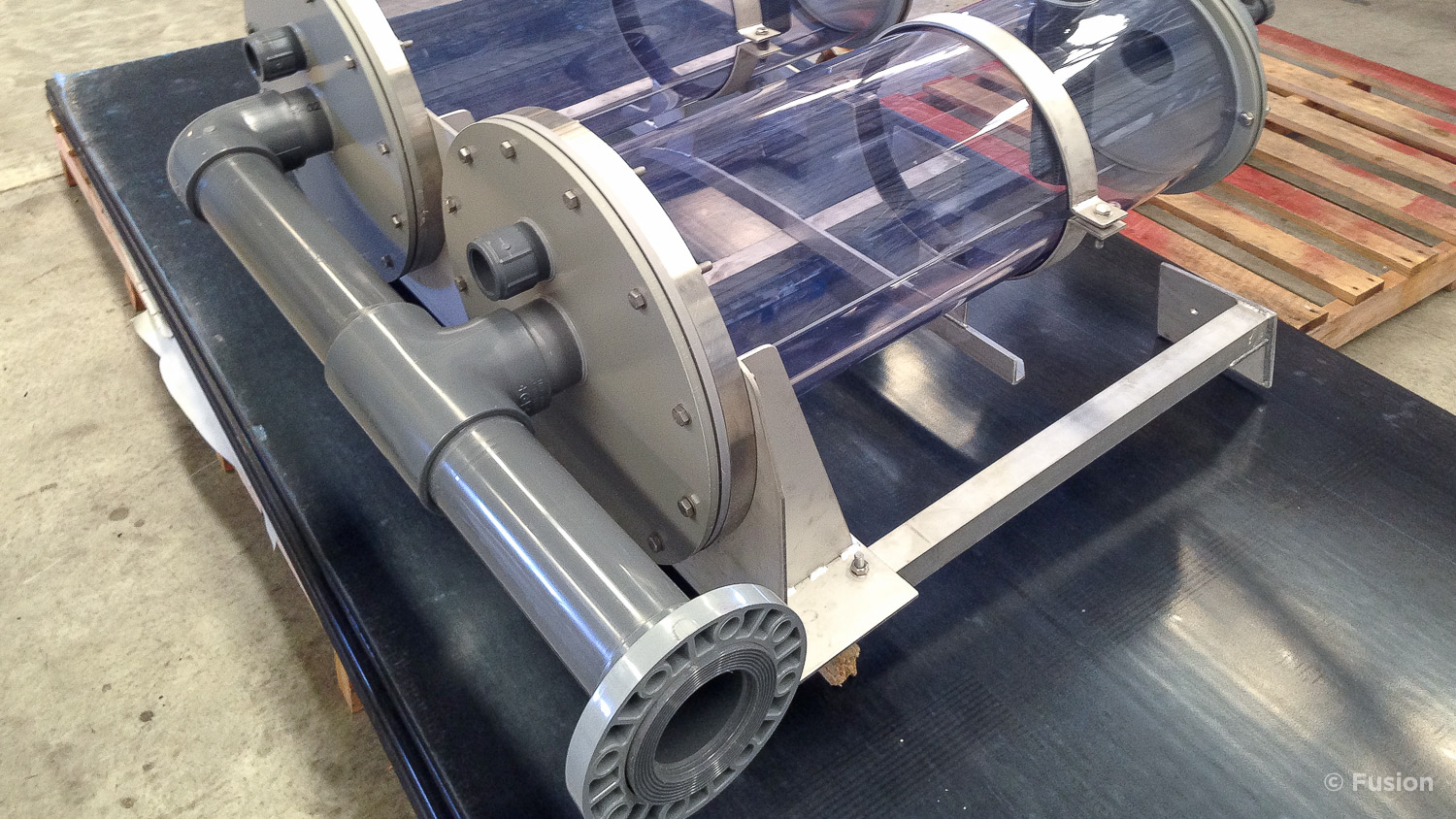

Fusion can fabricate scrubbers from high quality thermoplastics such as HDPE, UPVC and PP. Thermoplastics have high impact and corrosion resistant properties and are lower in cost to fabricate in comparison to stainless steel and fibreglass options; they’re also a lot easier to repair, if required.

Thermoplastic scrubbers require less maintenance and offer a longer design life meaning reduced operating costs and overall cost savings.

Using design software and Finite Element Analysis (FEA), we can custom design complex plastic structures.

Our engineering team has experience in mechanical design for scrubbers and degassing systems (read our article on degassing systems) which use gas-liquid contact mechanisms.

With a proven track record, we are ready to assist you with the design and build of your next Scrubber project.