Fusion’s WA fabrication team custom-built massive HDPE holding tanks, with the largest spanning over 23 meters in length, for the Brolos/Geraldton Fishermen’s Co-operative facilities in Geraldton and Welshpool (WA). These tanks maintain chilled, oxygen-rich, filtered seawater to keep hundreds of live lobsters vigorous during storage and transit.

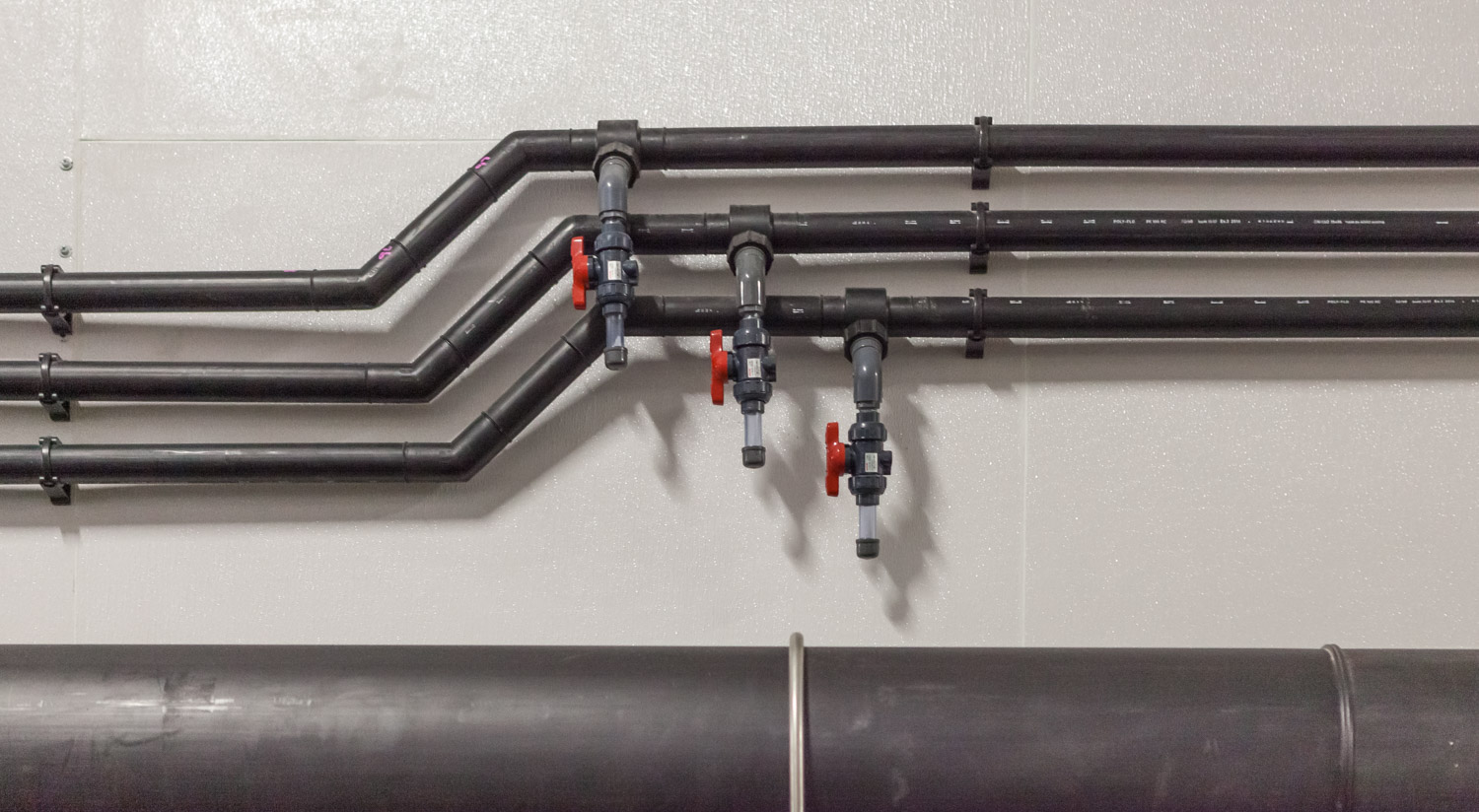

In a new lobster processing facility (Welshpool, WA), Fusion engineered and installed an extensive network of thermoplastic piping to support critical water chilling and cleaning operations. This included glycol transfer pipelines (HDPE) that circulate refrigerated glycol between chillers and the tanks for precise temperature control, as well as caustic soda Cleaning-In-Place (CIP) lines (in corrosion-resistant uPVC/PP) that allow automated wash-down and sterilization of the system between batches.

Food-Safe and Corrosion-Resistant: Materials like HDPE, polypropylene and rigid PVC are inert and food-grade, meaning they won’t rust or leach harmful substances into the water. In harsh marine environments, these plastics resist salt, chlorides, acids, caustics and microbes far better than traditional materials such as stainless steel, fiberglass, or concrete. Unlike metals, plastic tanks/pipes do not corrode or introduce heavy metals; unlike concrete, they do not shed lime or raise alkalinity of the water. This corrosion resistance prevents contamination and impurity buildup in the system, directly boosting lobster health and shelf-life. (For example, concrete surfaces can make water highly alkaline and require sealing, and fiberglass resin may degrade over time – issues avoided entirely with HDPE or PVC.) Thermoplastics also meet potable water and food contact standards, ensuring no toxic risk to the crustaceans or consumers.

Engineering Precision & Seamless Construction: Thermoplastics can be welded together into complex geometries and large-format structures with a high degree of precision. Fusion’s ability to butt-weld plastic panels yields homogenous joints that are as strong as the base material, creating essentially one-piece tanks and piping runs. This is crucial for extra-large tanks exceeding 20 m – a scale at which materials like concrete or fiberglass would require numerous joints or heavy reinforcement. In the WA project, Fusion joined HDPE sheets into continuous 23 m stretches for the tank walls and base. The use of computerized welding equipment and adherence to DVS/ISO thermoplastic welding standards ensure each weld is leak-proof and structurally sound, even for very long spans. The plastics can also be CNC machined and fabricated into custom shapes (like rounded corners, baffles, or specialized inlets) with millimetric accuracy. This level of design flexibility and “welded not bolted” construction yields seamless, crevice-free surfaces that are easy to clean and do not harbor bacteria.

Optimized for Recirculating Aquaculture: Modern Recirculating Aquaculture Systems (RAS) around the world rely overwhelmingly on plastic tanks and piping, and lobster RAS is no exception. The reason is consistency and control: thermoplastic systems do not react with water treatment components like ozone or UV, and they integrate readily with filters, pumps, and sterilizers. In lobster culture, maintaining stable water quality is critical – any spike in ammonia, bacterial load, or temperature can be fatal to the stock.

Thermoplastic tanks have smooth, non-porous interiors that minimize biofilm and algae attachment, making sanitation easier than in porous concrete or wood tanks. In fact, operators report significantly lower bacterial counts in plastic tanks versus fiberglass, and correspondingly improved survival and growth rates for the animals. Studies on lobster larval rearing have shown that reducing bacterial load in the water can directly increase larval survival, underscoring the importance of hygienic, inert tank materials.

Furthermore, plastics absorb less heat than metal or concrete, aiding in temperature stability – and they insulate better, which can reduce chilling costs. The inertness of HDPE and PVC also means they can handle the use of ozone and UV disinfection (commonly used in RAS) without degrading or producing disinfection by-products that could harm the lobsters. Globally, as RAS technology advances, thermoplastic infrastructure has become the norm for pipes and tanks because it reliably delivers the water quality needed for healthy, high-density aquaculture. In short, thermoplastics allow lobster farmers to create a controlled mini-ecosystem (stable salinity, pH, temperature, low bacteria) that would be very difficult to achieve with legacy materials.

Fusion brings a compelling value proposition to aquaculture and seafood projects, combining materials expertise with end-to-end project delivery: