IR welding uses a controlled infrared heat source positioned between two prepared pipe ends. The infrared energy penetrates and heats the joint surfaces without physical contact, eliminating the risk of particulates from the heating tool embedding into the weld.

For PVDF pipe, this results in:

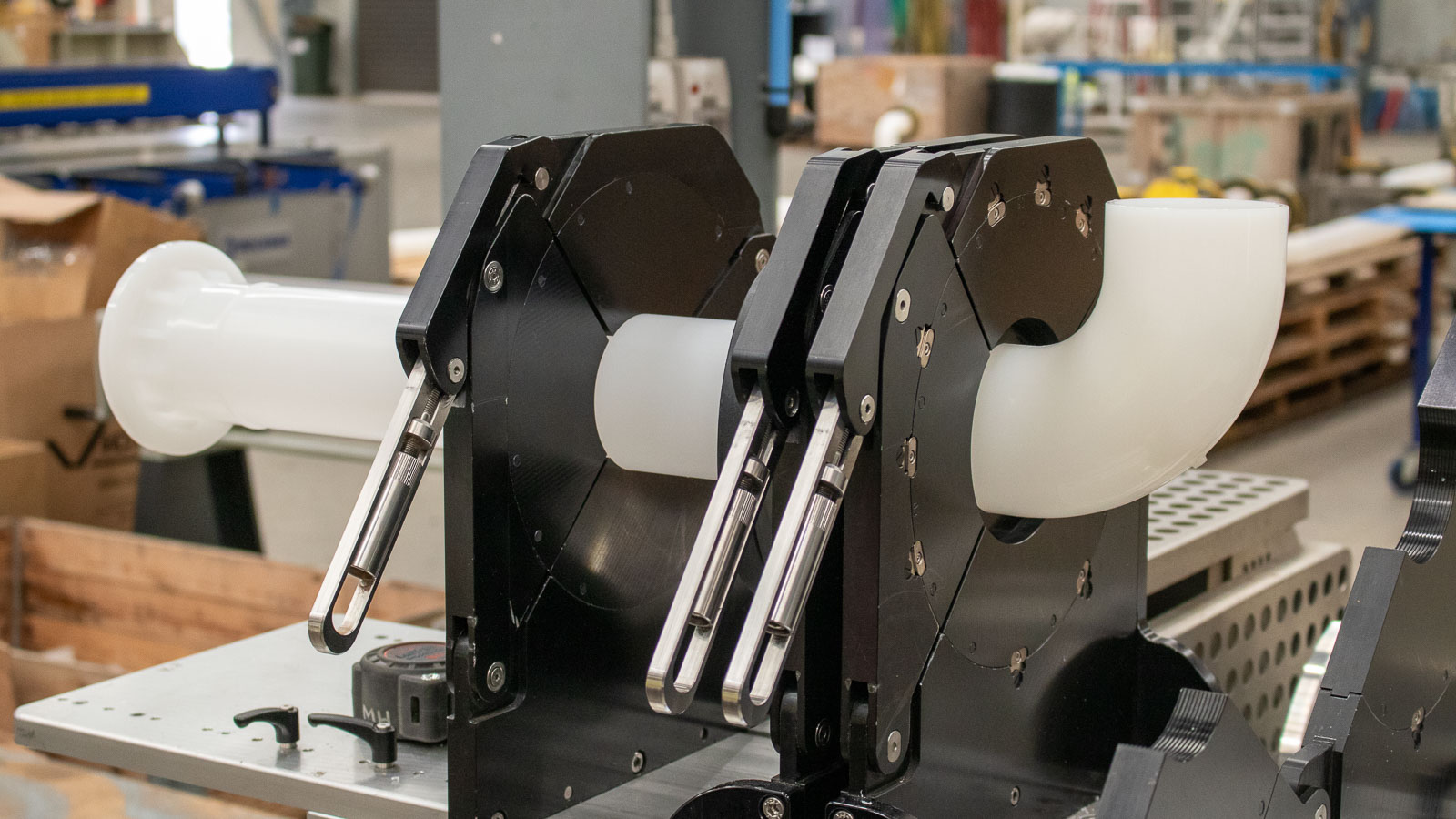

IR Welding Machine: Designed specifically for thermoplastic pipe with programmable settings for temperature, heating time, change-over time, and joining force.

Infrared Emitter: Matched to PVDF’s absorption spectrum for efficient, uniform heating.

Precision Clamping & Alignment System: Holds pipe and fittings square to maintain bore alignment.

PLC Controls & Data Logging: Records weld parameters for traceability and quality assurance.

PVDF: Primary use for IR welding due to high purity requirements in pharmaceutical, semiconductor, and chemical processing industries.

PE (Polyethylene): Suitable for water and chemical service where contactless heating is advantageous.

PP (Polypropylene): Used in high-temperature, chemical-resistant systems where clean internal surfaces are beneficial.

IR welding of PVDF pipe is widely used in:

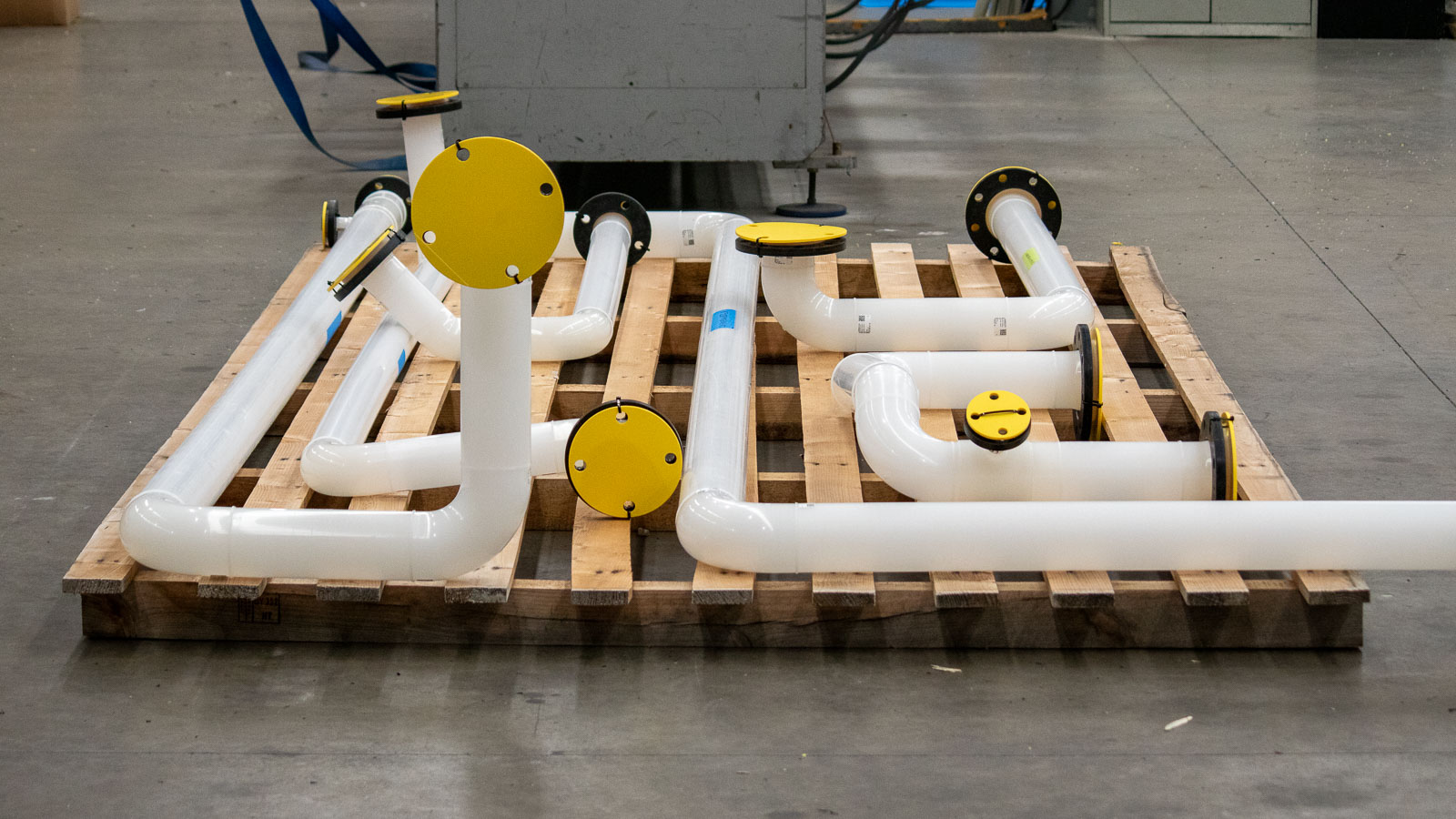

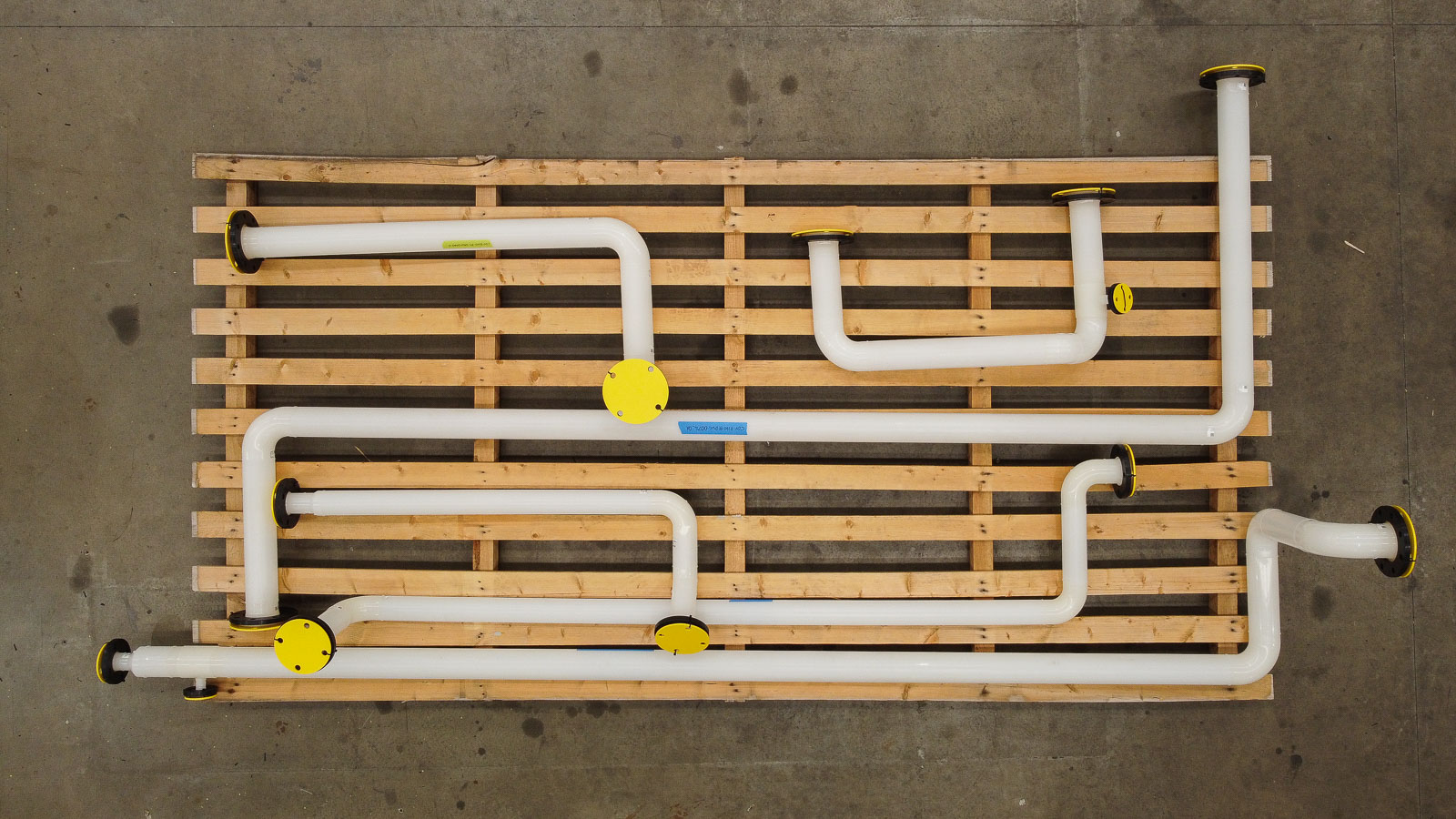

Fusion's in-house plastic fabrication team are experts in IR welding. Check out some of our recent work or contact us today for assistance with your next installation project!

Fusion Plastics boasts in-house plastic fabrication facilities located on both the east and west coasts of Australia. These facilities are equipped with advanced tools and machinery to handle complex fabrication projects involving PVDF, HDPE, PP and other thermoplastics.

In addition to our fabrication facilities, Fusion Plastics offers comprehensive site services staffed by trained professionals skilled in plastic welding techniques, including butt welding.

Challenges:

Tips:

We maintain our IR welding machines to ensure stable, repeatable performance. Welds are inspected visually and, where required, undergo additional destructive or non-destructive testing. Full QA documentation, including parameter logs, can be supplied for installations in validated systems.

When welding PVDF pipe, IR welding is the gold standard for contamination-free joints. Its non-contact heating preserves material integrity, ensures high-purity performance, and produces reliable, repeatable results. Whether for semiconductor manufacturing, pharmaceutical process lines, or aggressive chemical service, Fusion delivers PVDF IR welding to the highest industry standards in Australia.

Fusion's in-house plastic fabrication team are experts in IR welding. Check out some of our recent work or contact us today for assistance with your next installation project!