Easily join UPVC and CPVC pipe, fittings and valves using solvent cement and primer by Weld-On. Weld-on Adhesives Inc. is a California based, ISO 9001: 2008 certified company, globally recognised for its premium products for joining plastic piping systems.

Find out more by downloading the Fusion Product Guide, a comprehensive catalogue of piping systems, valves, level instrumentation and accessories.

IPSP70-473

1 pint / 473ml

IPSP70-946

1 quart / 946ml

Conforms to:

ASTM F 656

NSF/ANSI 14 & 61

IPS711-473

1 pint / 473ml

IPS711-946

1 quart / 946ml

Conforms to:

ASTM D 2564

NSF/ANSI 14 & 61

CSA B137.3 & B181.2

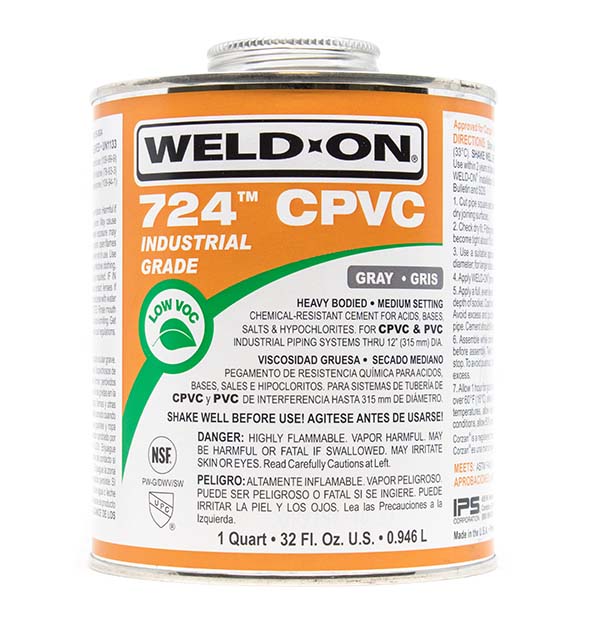

IPS724-473

1 pint / 473ml

IPS724-946

1 quart / 946ml

Conforms to:

ASTM F 493

NSF/ANSI 14 & 61

For specific, comprehensive instructions please refer to the manufacturer's guides, the instructions provided above are a general guide only. Below are two videos provided by Weld-On for small and large diameter pipe jointing. Further information about Weld-on solvent cement and primer can be viewed on the Weld-On website.

They are available directly from the manufacturer. Here are direct links:

Weld-On 711 (PVC) and 724 (CPVC) are industrial-grade solvent cements designed for high-performance, high-reliability applications. They offer stronger bonding, superior gap-filling, and proven long-term performance under pressure and temperature extremes. Both meet stringent international standards (ASTM, NSF, UPC, IAPMO) and are GreenGuard Gold certified for low VOCs. Weld-On 724 also provides exceptional chemical resistance, making it ideal for aggressive industrial environments.

Cheaper cements, like typical hardware store options, may be fine for light-duty or residential work but generally lack the certifications, chemical resistance, and industrial durability required for demanding projects.