CouplingImperial x Metric Socket

A uPVC adaptor coupling designed to connect imperial size plastic pipes to metric size plastic pipes. Featuring socket connections at both ends, it provides a secure and reliable transition between differing pipe standards, ensuring compatibility in water, chemical, and general fluid handling systems.

| Code [PN16] |

DN |

DN" |

L |

L1 |

Z |

E |

| 721913106 |

15 x d20 |

0.5" x d20 |

17 |

16 |

4 |

26 |

| 721913107 |

20 x d25 |

0.75" x d25 |

20 |

19 |

4 |

33 |

| 721913108 |

25 x d32 |

1" x d32 |

23 |

22 |

4 |

41 |

| 721913109 |

32 x d40 |

1.25" x d40 |

27 |

26 |

4 |

51 |

| 721913110 |

40 x d50 |

1.5" x d50 |

32 |

31 |

4 |

60 |

| 721913111 |

50 x d63 |

2" x d63 |

38 |

38 |

3 |

74 |

| 721913113 |

80 x d90 |

3" x d90 |

51 |

50 |

6 |

105 |

| 721913115 |

100 x d110 |

4" x d110 |

63 |

61 |

8 |

128 |

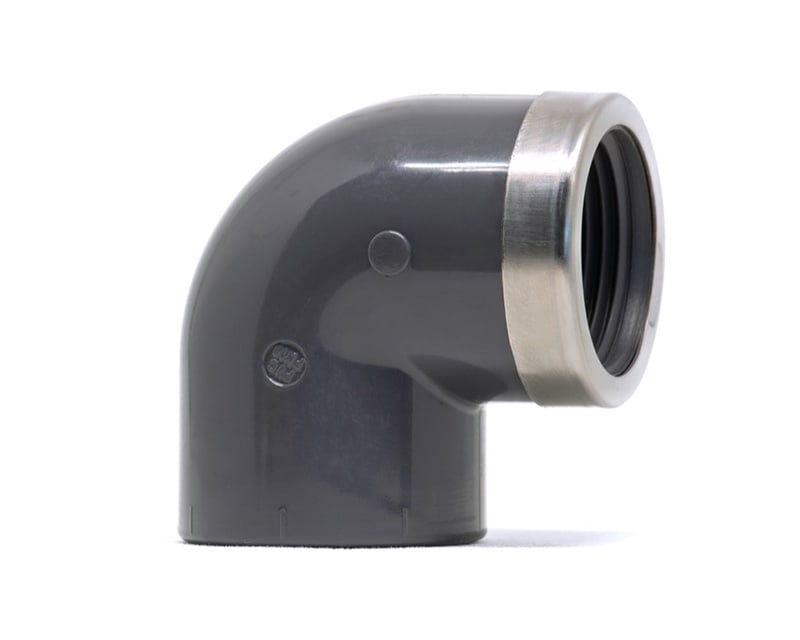

Elbow 90°Socket x Reinforced F-BSP

A uPVC British Standard 90-degree elbow with one socket end and one stainless steel reinforced female BSP threaded end.

| Code | DN | DN" | L1 | L2 | Z1 | Z2 | E |

|---|

| 721101206 | 15 | 0.5" | 17 | 15 | 11 | 13 | 28 |

| 721101207 | 20 | 0.75" | 20 | 16.3 | 14 | 17 | 34 |

| 721101208 | 25 | 1" | 23 | 19.1 | 17 | 21 | 42 |

Bend 90°Socket Ends

A uPVC 90-degree bend with socket connections at both ends. Manufactured to British Standard dimensions, it allows smooth directional changes in plastic piping systems while maintaining reliable, leak-free joints. Suitable for water, chemical, and general fluid handling applications.

| Code | DN | DN" | L | Z | E |

|---|

| 721001106 | 15 | 0.5" | 16 | 40 | 28 |

| 721001107 | 20 | 0.75" | 19 | 50 | 35 |

| 721001108 | 25 | 1" | 22 | 64 | 42 |

| 721001109 | 32 | 1.25" | 26 | 80 | 51 |

| 721001110 | 40 | 1.5" | 31 | 100 | 63 |

| 721001111 | 50 | 2" | 38 | 126 | 77 |

| 721001113 | 80 | 3" | 51 | 180 | 113 |

| 721001115 | 100 | 4" | 61 | 220 | 132 |

Tee 90°Sockets x Reinforced F-BSP

A uPVC 90-degree tee with socket connections on the main line and a female BSP threaded off-take. Designed for branching plastic piping systems to threaded components, it provides a durable and leak-resistant connection suitable for water, chemical, and general fluid handling applications.

| Code | DN | DN" | L1 | L2 | Z1 | Z2 | E |

|---|

| 721201206 | 15 | 0.5" | 17 | 15 | 11 | 13 | 28 |

| 721201207 | 20 | 0.75" | 19 | 16.3 | 14 | 17 | 34 |

| 721201208 | 25 | 1" | 23 | 19.1 | 17 | 21 | 42 |

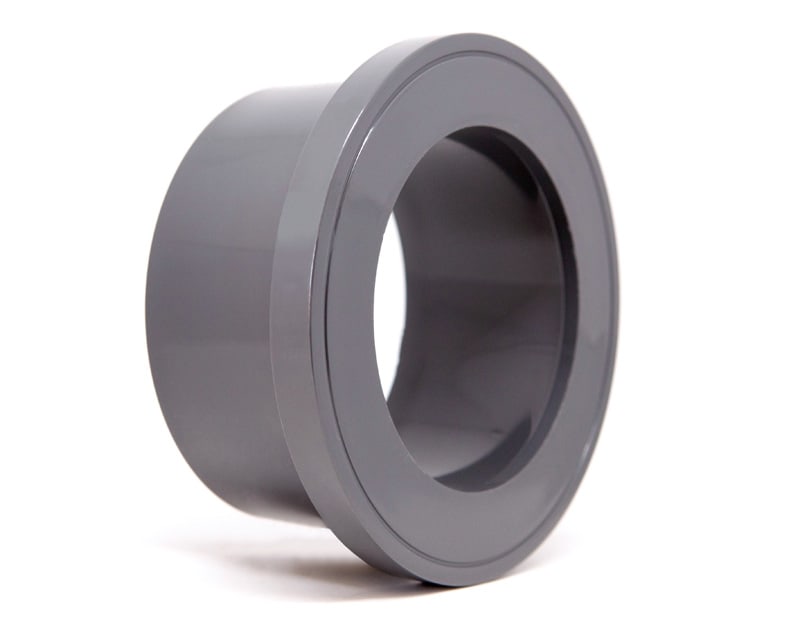

Stub FlangeSerrated Jointing Face x Socket

A uPVC stub flange with a serrated (raised) face, designed for solvent-weld pipe systems. It enables the creation of a robust, pressure-rated joint when paired with backing rings, a stub gasket, and suitable fasteners, making flange-to-flange connections straightforward.

| Code | DN | DN" | d1 | L | Z | E | F | S |

|---|

| 721791106 | 15 | 0.5" | 27 | 16 | 3 | 34 | 16 | 3 |

| 721791107 | 20 | 0.75" | 33 | 19 | 4 | 41 | 21 | 3 |

| 721791108 | 25 | 1" | 41 | 22 | 4 | 50 | 28 | 7 |

| 721791109 | 32 | 1.25" | 50 | 26 | 3 | 61 | 32 | 8 |

| 721791110 | 40 | 1.5" | 61 | 32 | 4 | 73 | 38 | 9 |

| 721791111 | 50 | 2" | 76 | 38 | 4 | 90 | 50 | 10 |

| 721791113 | 80 | 3" | 108 | 52 | 4 | 125 | 82 | 11 |

| 721791115 | 100 | 4" | 131 | 62 | 5 | 149 | 106 | 12 |

| 721791117 | 150 | 6" | 193 | 87 | 7 | 214 | 165 | 13 |

| 721791120 | 200 | *8" | 248 | 119 | 9 | 273 | 208 | 20 |

BushSpigot x F-BSP

A uPVC adaptor bush with a spigot end and a female BSP threaded end. Designed to convert plain-end plastic pipe to threaded connections, it provides a secure, durable joint between solvent-weld systems and BSP-threaded components.

| Code |

DN |

DN" |

| 721901534 |

15 x 10 |

0.5" x 0.375" |

| 721901537 |

20 x 15 |

0.75" x 0.5" |

| 721901542 |

25 x 15 |

1" x 0.5" |

| 721901541 |

25 x 20 |

1" x 0.75" |

Threaded AdaptorSocket x M-BSP

A versatile uPVC male adaptor with a solvent-weld socket end that can also double as a spigot and features a male BSP (BSPP) threaded connection.

| Code | DN [B/G] | DN" [B/G] | B1* | L | L1 | L2 | H |

|---|

| 721911706 | 15 | 0.5" | 0.75" | 17 | 20 | 15 | 46 |

| 721911707 | 20 | 0.75" | 1" | 20 | 23 | 16.3 | 50 |

| 721911708 | 25 | 1" | 1.25" | 23 | 27 | 19.1 | 57 |

| 721911709 | 32 | 1.25" | 1.5" | 27 | 32 | 21.4 | 67 |

| 721911710 | 40 | 1.5" | 2" | 32 | 39 | 21.4 | 74 |

| 721911711 | 50 | 2" | 2.5" | 39 | 44 | 25.7 | 84 |

Threaded AdaptorSpigot x M-BSP

A uPVC adaptor nipple with a spigot end and a male BSP threaded end. Designed for connecting solvent-weld plastic piping systems directly to BSP-threaded components.

| Code |

DN |

DN" |

L1 |

L2 |

| 721913906 |

15 |

0.5" |

50 |

16 |

| 721913907 |

20 |

0.75" |

56 |

17 |

| 721913908 |

25 |

1" |

63 |

20 |

| 721913909 |

32 |

1.25" |

75 |

24 |

| 721913910 |

40 |

1.5" |

88 |

30 |

| 721913911 |

50 |

2" |

88 |

32 |

| 721913913 |

80 |

3" |

128 |

39 |

| 721913915 |

100 |

4" |

153 |

43 |

Threaded AdaptorSocket x Reinforced F-BSP

A uPVC female adaptor with a solvent-weld socket end and a female BSP threaded connection.

| Code | DN | DN" | Z | B | D | S |

|---|

| 721911006 | 15 | 0.5" | 1 | 17 | 15 | 32 |

| 721911007 | 20 | 0.75" | 3 | 20 | 16 | 36 |

| 721911008 | 25 | 1" | 2 | 23 | 22 | 46 |

| 721911009 | 32 | 1.25" | 1 | 28 | 22 | 55 |

| 721911010 | 40 | 1.5" | 3 | 30 | 25 | 66 |

| 721911011 | 50 | 2" | 4 | 36 | 28 | 80 |

Threaded AdaptorSpigot x F-BSP

A uPVC female adaptor with a spigot end and a female BSP threaded connection.

| Code |

DN |

DN" |

L1 |

L2 |

H |

| 721901406 |

15 |

0.5" |

17 |

15 |

40 |

| 721901407 |

20 |

0.75" |

20 |

16.3 |

45 |

| 721901408 |

25 |

1" |

23 |

19.1 |

51 |

| 721901409 |

32 |

1.25" |

27 |

21.4 |

58 |

| 721901410 |

40 |

1.5" |

32 |

21.4 |

64 |

| 721901411 |

50 |

2" |

39 |

26 |

75 |

Threaded AdaptorM-BSP Ends

A uPVC straight adaptor with male BSPP threads on both ends. Designed to join or extend threaded components, it provides a durable and leak-resistant connection suitable for water, chemical, and general fluid handling applications.

| Code |

DN |

DN" |

L min |

H |

| 721911906 |

15 |

0.5" |

15 |

42 |

| 721911907 |

20 |

0.75" |

16.3 |

45 |

| 721911908 |

25 |

1" |

19.1 |

50 |

| 721911909 |

32 |

1.25" |

21.4 |

58 |

| 721911910 |

40 |

1.5" |

21.4 |

58 |

| 721911911 |

50 |

2" |

25.7 |

67 |

Threaded AdaptorM-BSP x F-BSP

A uPVC threaded reducing adaptor with a female BSPP thread on one end and a larger male BSPP thread on the other. Designed to connect components of different BSPP thread sizes, it provides a secure, corrosion-resistant transition suitable for water, chemical, and general fluid handling systems.

| Code | DN | DN" | L1 | L2 | H | E |

|---|

| 721910834 | 15 x 10 | 0.5" x 0.375" | 15 | 11.4 | 36 | 23 |

| 721910837 | 20 x 15 | 0.75" x 0.5" | 16.3 | 15 | 41 | 28 |

| 721910842 | 25 x 15 | 1" x 0.5" | 19.1 | 15 | 43 | 28 |

| 721910841 | 25 x 20 | 1" x 0.75" | 19.1 | 16.3 | 45 | 34 |

| 721910846 | 32 x 25 | 1.25" x 1" | 21.4 | 19.1 | 51 | 42 |

| 721910852 | 40 x 32 | 1.5" x 1.25" | 21.4 | 21.4 | 55 | 51 |

| 721910858 | 50 x 40 | 2" x 1.5" | 26 | 21.4 | 57 | 58 |

UnionSocket Ends

A uPVC union featuring solvent-weld (British Standard) ends, designed to join two pipes of the same nominal size securely under pressure while allowing for easy disassembly or maintenance. It combines reliable connection integrity with the flexibility of quick servicing—ideal for applications in water handling, chemical processing, and general fluid systems.

| EPDM Code |

DN |

DN" |

L min |

Z max |

H |

E |

F |

| 721511106 |

15 |

0.5" |

16 |

13 |

42 |

43 |

1" |

| 721511107 |

20 |

0.75" |

19 |

13 |

51 |

54 |

1.25" |

| 721511108 |

25 |

1" |

22 |

13 |

57 |

61 |

1.5" |

| 721511109 |

32 |

1.25" |

27 |

14 |

68 |

75 |

2" |

| 721511110 |

40 |

1.5" |

31 |

18 |

80 |

81 |

2.25" |

| 721511111 |

50 |

2" |

38 |

22 |

98 |

99 |

2.75" |

UnionF-BSP Ends

A uPVC threaded union with female BSPP threads on both ends, designed to join two threaded components securely while allowing for easy disassembly and maintenance.

| EPDM Code |

DN |

DN" |

L min |

Z Max |

H |

E |

F |

| 721510606 |

15 |

0.5" |

15 |

15.5 |

45.5 |

43 |

1" |

| 721510607 |

20 |

0.75" |

16.3 |

19.4 |

52 |

54 |

1.25" |

| 721510608 |

25 |

1" |

19.5 |

19 |

58 |

61 |

1.5" |

| 721510609 |

32 |

1.25" |

21.4 |

25.7 |

68.5 |

75 |

2" |

| 721510610 |

40 |

1.5" |

21.4 |

37.2 |

80 |

81 |

2.25" |

| 721510611 |

50 |

2" |

25.7 |

46.6 |

98 |

99 |

2.75" |

Union Parts

Replacement parts for uPVC unions, supplied individually. Options include female BSPP threaded ends, metric solvent-weld socket ends, and FPM (Viton®) seals. Designed to be used with the corresponding full union body, these spare parts ensure long service life, easy maintenance, and continued reliability of the piping system.

| DN |

DN"

| 1 x FPM Seal |

1 x F-BSP End |

Size |

1 x Metric End |

| 15 |

0.5" |

1.3.16.050 |

1.3.17.050 |

d20 |

1.3.18.050 |

| 20 |

0.75" |

1.3.16.075 |

1.3.17.075 |

d25 |

1.3.18.075 |

| 25 |

1" |

1.3.16.100 |

1.3.17.100 |

d32 |

1.3.18.100 |

| 32 |

1.25" |

1.3.16.125 |

1.3.17.125 |

d40 |

1.3.18.125 |

| 40 |

1.5" |

1.3.16.150 |

1.3.17.150 |

d50 |

1.3.18.150 |

| 50 |

2" |

1.3.16.200 |

1.3.17.200 |

d63 |

1.3.18.200 |

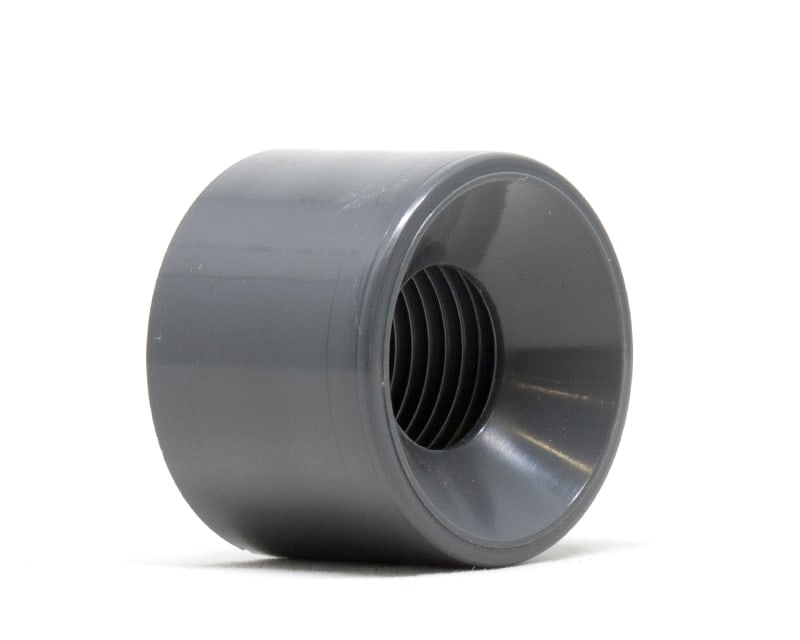

CapF-BSP End

A uPVC end cap with a female BSPP threaded connection. Designed to securely close off the end of a threaded pipeline or fitting.

| Code |

DN |

DN" |

L |

H |

E |

CH |

| 721960606 |

15 |

0.5" |

15 |

26 |

28 |

30 |

| 721960607 |

20 |

0.75" |

16.3 |

28 |

34 |

36 |

| 721960608 |

25 |

1" |

19.1 |

32 |

42 |

46 |

| 721960609 |

32 |

1.25" |

21.4 |

35 |

51 |

55 |

| 721960610 |

40 |

1.5" |

21.4 |

35 |

58 |

60 |

| 721960611 |

50 |

2" |

26 |

39 |

72 |

75 |

PlugM-BSP End

A uPVC plug with a male BSPP threaded connection. Designed to seal off female-threaded fittings or pipeline ends.

| Code |

DN |

DN" |

L |

H |

CH |

| 721961906 |

15 |

0.5" |

15 |

29 |

24 |

| 721961907 |

20 |

0.75" |

16.3 |

30 |

30 |

| 721961908 |

25 |

1" |

19.1 |

33 |

36 |

| 721961909 |

32 |

1.25" |

21.4 |

39 |

46 |

| 721961910 |

40 |

1.5" |

21.4 |

39 |

50 |

| 721961911 |

50 |

2" |

26 |

43 |

65 |

Hose ConnectorM-BSP x Hose End

A versatile uPVC hose adaptor with a BSPP male thread on one end and a hose-tail barb on the other. Designed to connect flexible hoses to threaded plastic systems securely, it delivers a durable, leak-resistant transition ideal for water, chemical, and general fluid-handling applications.

| Code |

DN |

DN" |

d1 |

d2 |

L |

H |

CH |

| 721960705 |

10 |

0.375" |

16 |

18 |

12 |

64 |

19 |

| 721960706 |

15 |

0.5" |

20 |

22 |

15 |

70 |

24 |

| 721960707 |

20 |

0.75" |

25 |

27 |

17 |

76 |

30 |

| 721960708 |

25 |

1" |

32 |

34 |

20 |

80 |

36 |

| 721960709 |

32 |

1.25" |

40 |

42 |

22 |

92 |

46 |

Tank AdaptorSpigot x M-BSP End

A uPVC tank adaptor set consisting of a toe nipple, two threaded nuts, and an EPDM seal gasket. Designed for installing a secure, leak-tight connection through the wall of a tank, it allows reliable attachment of pipework or fittings to storage and process vessels.

| EPDM Code |

DN |

DN" |

L1 |

L2 |

O |

| 161051226 |

15 |

0.5" |

77 |

42 |

38 |

| 161051227 |

20 |

0.75" |

77 |

42 |

42 |

| 161051228 |

25 |

1" |

103 |

55 |

55 |

| 161051229 |

32 |

1.25" |

121 |

70 |

65 |

| 161051230 |

40 |

1.5" |

128 |

73 |

72 |

| 161051231 |

50 |

2" |

154 |

82 |

93 |

Searching…

No results found.

Searching…