Fusion's workshop teams are custom plastic fabrication experts. Whether you require large (or small) chemical storage tanks, bunds, dosing panels, pipe spools, chutes / launders, electrowinning cells, machine / motor guards, ballasts / floats or something unique, our workshop fabricators can provide a solution.

We provide plastic fabricated products for clients who experience frequent maintenance problems caused by aggressive chemical corrosion and are seeking an alternative to steel.

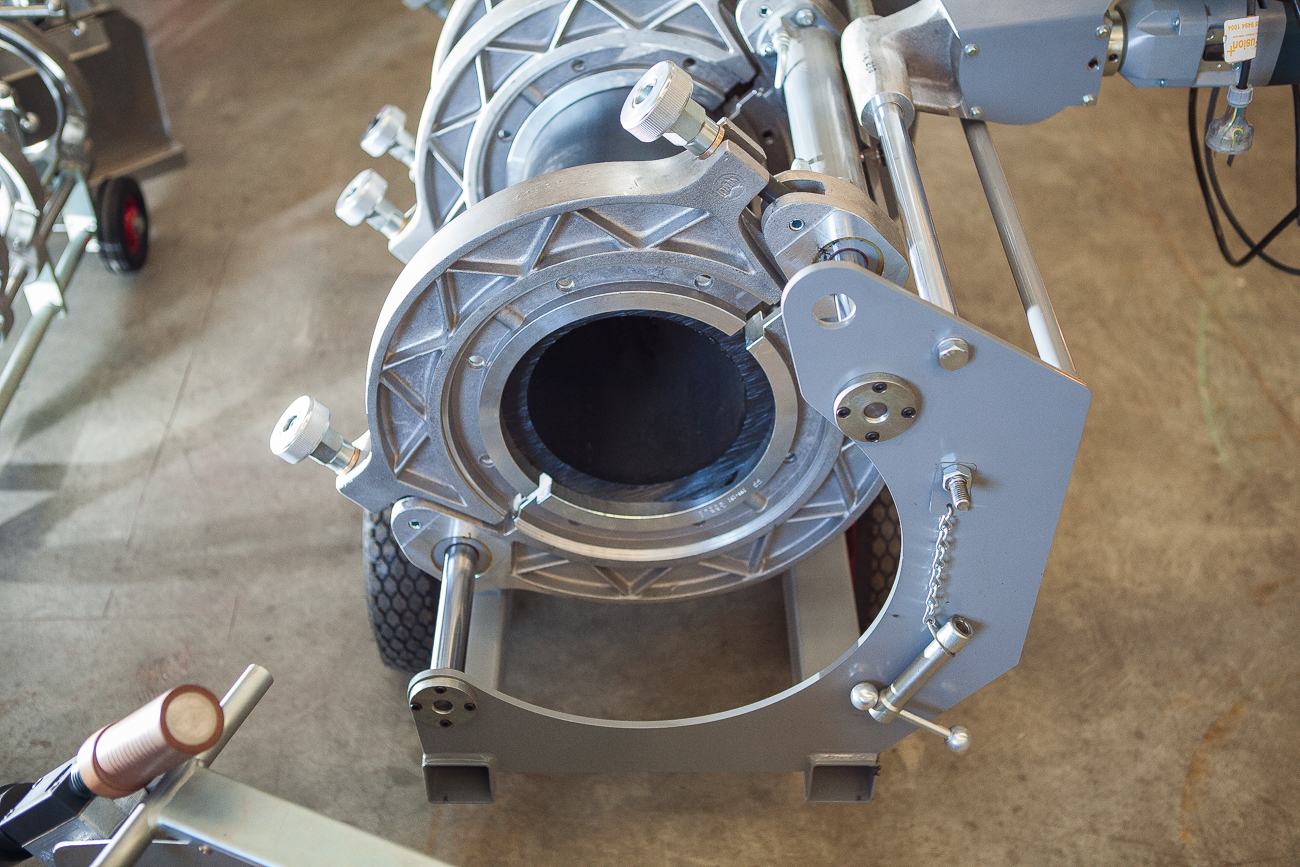

Our core fabrication capabilities include sheet butt welding, extrusion welding, piping systems welding (including butt, socket, IR, glue jointing) and CNC cutting.

Interested in our plastic fabrication services?

Fusion's fabrication experts hold the qualifications and training to provide installation, maintenance and site services at your location. Whether it's a scheduled shutdown for maintenance / upgrades, an emergency call out for repair, laying HDPE pipe for critical water services or a new plant build; our staff have a long history assisting clients throughout Australia and internationally.

Interested in our site services capabilities for your next project?

Our engineering team works directly with consulting engineers, project managers, operations managers and business owners across Australia.

The engineers who make up Fusion’s design and innovation team are specialists in the design of plastic tanks, piping systems and dosing panels for delivery or movement of chemicals for water treatment and chemical processing across a range of industries spanning water treatment, mining, food and beverage, paper and pulp, chemical production and more.

With a dedicated team of engineers specialising in tanks, pipes and values, we can provide expert plastics engineering advice, review existing drawings, or collaborate with you on a custom design that delivers maximum efficiency and effectiveness, so you get the best solution for your project.

Require our engineering services for your next project?