Dosing panels play a critical role in various industries, ensuring the safe containment of essential piping infrastructure. These systems are prevalent in water treatment plants, mining processes, food and beverage manufacturing, and pharmaceutical facilities. Given their importance, understanding their function, construction, and the latest trends is vital for industry professionals.

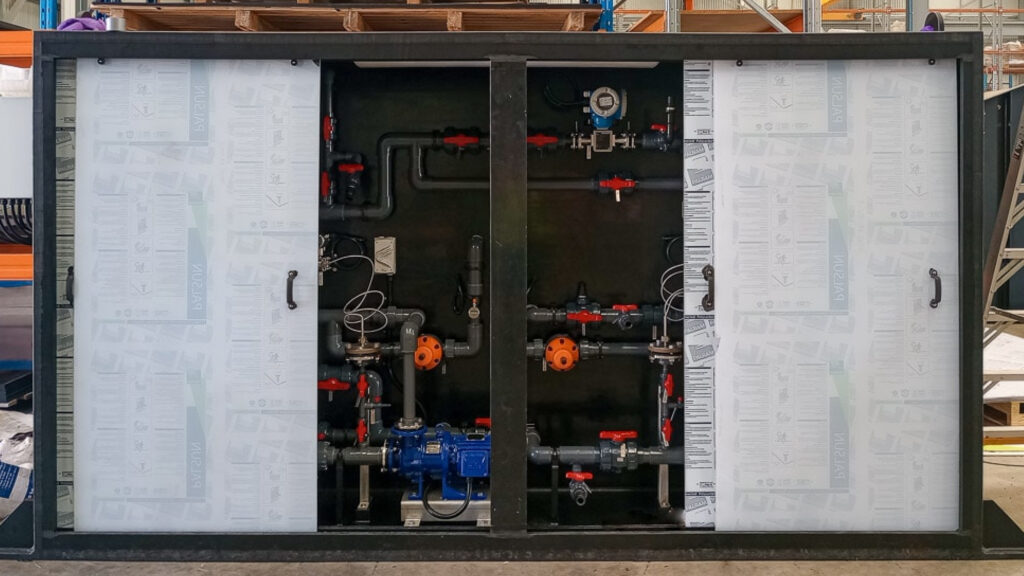

Dosing panels are integral components in many commercial and industrial processes. They house equipment such as piping, fittings, valves, pumps, and analytical instruments used to manually or automatically dose chemicals into processes. These systems are essential for manufacturing goods, cleaning equipment, treating water, and other applications. To safeguard staff and the environment, these components are often housed in dosing cabinets or panels, which provide a barrier against spills and potential hazards.

In industries that use chemicals, it is crucial to maintain and adjust the dosing equipment. To address this need, dosing panels and cabinets have been developed to house the piping systems in a protective enclosure. This not only increases safety by reducing the risk of spillage but also helps organise the complex network of pipes and valves, making maintenance more manageable.

Fusion custom manufactures these dosing cabinets to match the specific size and design of the client's piping systems. They recommend the most suitable plastic for the client's chemicals and environment to ensure maximum safety and longevity, commonly using HDPE (High-Density Polyethylene) or PP (Polypropylene). Fusion’s fabrication and engineering teams provide a complete turn-key solution, from designing and assembling the process pipework to hydrotesting and on-site installation. They also coordinate the electrical installation, ensuring a comprehensive service

As safety standards continue to evolve to protect the environment and personnel, there has been a notable shift towards more comprehensive safety measures. Clients are increasingly seeking to retrofit cabinetry around existing pipework. Fusion has worked extensively with the Water Corporation to retrofit cabinets to in-situ pipework, enhancing personnel safety. Fusion’s dosing cabinets are designed with features such as lifting lugs, tie-down feet, and auto-closing doors to meet these stringent safety standards.

Dosing panels are not limited to a single industry; their applications are widespread and varied. Water treatment plants are crucial for managing the precise dosing of chemicals needed to purify water. In the mining industry, dosing panels ensure that hazardous chemicals are handled safely and efficiently during the extraction and processing of minerals.

The food and beverage industry relies on these panels to maintain strict hygiene standards during the cleaning and production processes, particularly in CIP (clean-in-place) systems. Pharmaceutical companies also benefit from dosing panels by maintaining the integrity of their chemical processes, which is essential for producing safe and effective medications.

Fusion’s custom solutions offer significant advantages over standard dosing panels. By tailoring the design to the specific requirements of each client, we ensure that the dosing panels fit perfectly within the existing infrastructure, optimising space and enhancing functionality. The use of high-quality materials such as HDPE and PP not only extends the lifespan of the panels but also provides superior resistance to the harsh chemicals often used in industrial processes. Additionally, our comprehensive service, from design to installation, reduces the need for multiple contractors, streamlining project management and ensuring consistent quality and safety standards throughout the project lifecycle.

When it comes to managing large-scale industrial projects, we bring a wealth of experience and expertise to the table. With our comprehensive resources and skilled team, we're fully equipped to handle projects of any size with confidence and efficiency. Our commitment to delivering top-quality results drives everything we do, ensuring that your needs are met with precision and excellence.

For more detailed examples and extensive information, visit our dedicated Chemical Dosing Panels page on our website.

One common trend has been towards fully enclosed designs over safety curtains. Fully enclosed designs are longer-lasting and less prone to leaks, making them a preferable option for many clients. Another issue is space constraints, which Fusion addresses by custom-designing cabinets to minimise the extra space required.

Fusion's sister company, Snosko, offers pre-designed dosing cabinets that utilise advanced components, minimising the internal pipework required for chemical dosing. This innovation generally allows for a smaller footprint, making these cabinets suitable for space-constrained environments. More information about Snosko’s dosing system can be viewed here.

Fusion’s dosing panels and cabinets offer several benefits:

Dosing panels and cabinets are vital for the safe and efficient operation of many industrial processes. Fusion’s custom solutions ensure that each system is tailored to the client’s specific needs, using high-quality materials and innovative design features to enhance safety and functionality. With a strong focus on meeting evolving safety standards and addressing common industry challenges, Fusion continues to be a reliable partner for industries requiring advanced dosing solutions.

For more information on Fusion’s dosing panels and cabinets, and to explore our extensive range of services, visit the website.